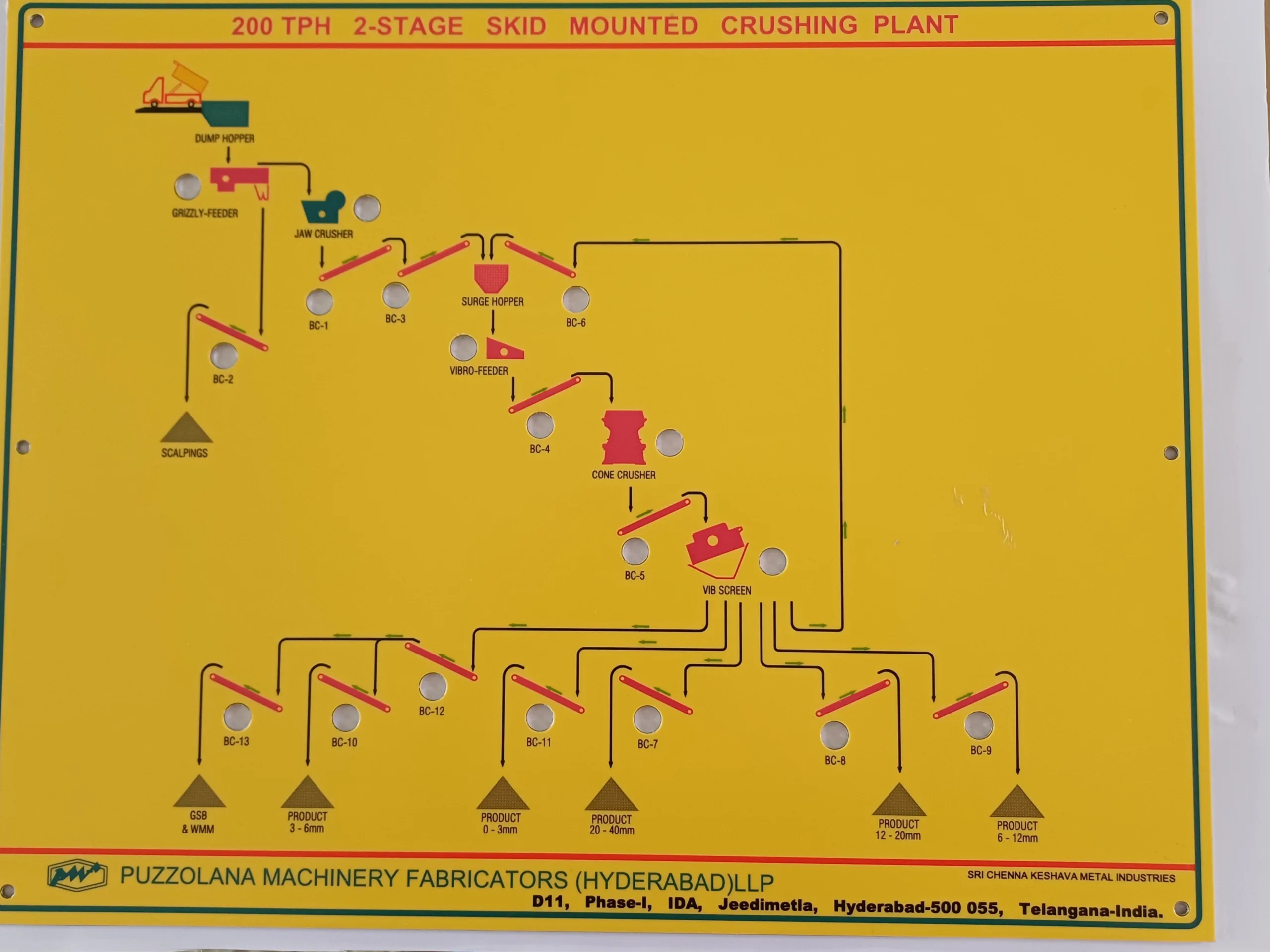

Our manufacturing process is meticulously designed to ensure the highest quality and precision in every Mimic Panel we produce. Our process encompasses the following steps:

Design and Engineering: We work closely with you to understand your requirements and create a detailed blueprint for your Mimic Panels, considering dimensions, cut-outs, colors, and industry standards.

Material Selection: We offer a range of materials, including anodized aluminum and polymers, helping you choose the most suitable material for durability, aesthetics, and compatibility with your industrial environment.

CNC Machining: Our state-of-the-art CNC machining techniques enable us to achieve precise cut-outs, pitch, and specifications, ensuring seamless integration with switches, displays, and other components.

Printing and Finishing: Using specialized printing techniques, we transfer your desired colors and designs onto the panel surface, ensuring vibrant and long-lasting visuals. We also apply a protective coating for enhanced durability.

Quality Control: Before packaging and delivery, our dedicated quality control team conducts rigorous checks for visual appearance, dimensional accuracy, and functionality, ensuring only the finest panels are shipped to you.

Packaging and Delivery: We carefully package your Mimic Panels to ensure they arrive in pristine condition. We utilize appropriate packaging materials and work with reliable shipping partners to deliver your panels securely and on time.

We prioritize craftsmanship, precision, and quality control throughout our manufacturing process. Trust us to bring your vision to life and provide you with superior Mimic Panels tailored to your exact requirements.