PHARMA/ON-SITE SIGNAGE

Pharma nameplate / ON-SITE SIGNAGE :

with over 30+ years of experience in the manufacturing of nameplates. serving the top 400 + pharma companies, we ship worldwide, the trusted pharma nameplate manufacturer

Pharmaceutical companies require specific types of nameplates to ensure compliance with regulatory standards and maintain a clean, professional environment. Here are some common types of pharma nameplates:

1. Equipment Nameplates:

- Material: Stainless steel or other durable, easy-to-clean materials.

- Information:

- Equipment name and model number

- Manufacturer’s name and logo

- Serial number

- Calibration and maintenance schedules

- Safety instructions and warnings

- Regulatory compliance information (e.g., CE, FDA)

2. Laboratory Nameplates:

- Material: Chemical-resistant materials like acrylic or stainless steel.

- Information:

- Laboratory name and purpose

- Authorized personnel

- Safety guidelines and emergency procedures

- Chemical storage and handling instructions

3. Office Nameplates:

- Material: Acrylic, wood, or metal.

- Information:

- Employee name and job title

- Department or team name

- Contact information (phone number, email)

4. Safety Signs and Labels:

- Material: Durable, weather-resistant materials like vinyl or aluminum.

- Information:

- Hazard warnings (e.g., flammable, corrosive, toxic)

- Safety instructions (e.g., wear PPE, no smoking)

- Emergency exits and first aid locations

5. Regulatory Compliance Labels:

- Material: Durable, weather-resistant materials.

- Information:

- Regulatory agency logos and certifications (e.g., FDA, GMP)

- Batch and expiration dates

- Storage conditions

- Lot numbers

Key Considerations for Pharma Nameplates:

- Durability: The nameplates must withstand harsh cleaning chemicals and sterilization processes.

- Legibility: The information should be clear and easy to read, even from a distance.

- Adhesion: The nameplates must adhere securely to the surface, especially in high-traffic areas.

- Chemical Resistance: The material should be resistant to chemicals and solvents commonly used in pharmaceutical environments.

- Regulatory Compliance: The nameplates must comply with all relevant regulations, including FDA guidelines.

By using high-quality, durable, and informative nameplates, pharmaceutical companies can improve safety, efficiency, and regulatory compliance.

Pharmaceutical labels and stickers are essential components of the pharmaceutical industry, serving a variety of purposes, including:

- Product Identification: Clearly identifying the product, its dosage, strength, and other relevant information.

- Regulatory Compliance: Adhering to strict regulatory standards and guidelines, such as those set by the FDA.

- Patient Safety: Providing essential information to patients and healthcare professionals to ensure safe and effective use of medications.

- Brand Recognition: Enhancing brand identity and building consumer trust.

- Supply Chain Management: Facilitating efficient tracking and management of products throughout the supply chain.

Types of Pharmaceutical Labels and Stickers:

- Product Labels:

- Primary Labels: Directly applied to the product packaging, providing essential information like product name, strength, dosage, expiration date, and manufacturer’s details.

- Secondary Labels: Additional labels that may be applied to the primary packaging, providing supplementary information or warnings.

- Warning Labels:

- Hazard Warning Labels: Indicate potential hazards associated with the product, such as flammability, toxicity, or reactivity.

- Caution Labels: Provide specific instructions or precautions for handling or using the product.

- Barcode Labels:

- Linear Barcodes: Used for basic product identification and tracking.

- 2D Barcodes: Can store more information, including lot numbers, expiration dates, and manufacturing details.

- Tamper-Evident Labels:

- Designed to indicate if a product has been tampered with, often used for high-value or sensitive medications.

- Temperature Indicator Labels:

- Change color or appearance when exposed to specific temperature ranges, ensuring proper storage and transportation conditions.

- Change color or appearance when exposed to specific temperature ranges, ensuring proper storage and transportation conditions.

Asset Labels

We manufacture Barcoded, Serial numbered, QR coded Polyester, Aluminum Asset tags and labels.

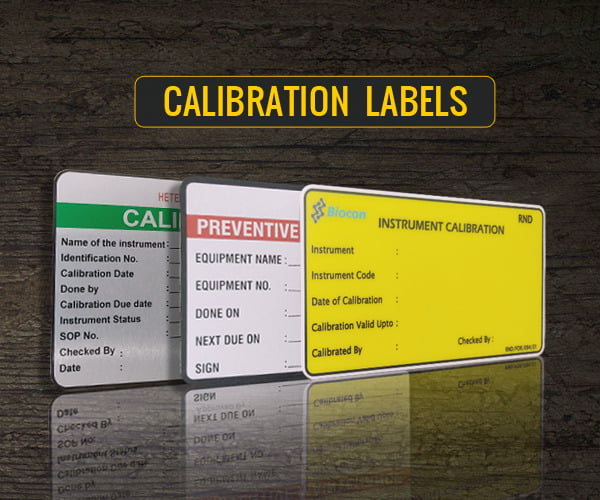

Calibration Labels

Calibration Labels for machine tools, heavy machines, pharmaceuticals, automobiles, and other industries

Safety Signage

Illuminate safety with our photoluminescent and self-illuminated signage options

Identification Labels

Polyester, Polycarbonate or Anodized Aluminum Identification Labels for organizing your office according to best practices of modern office organization and management

Pipeline & Tree Markers

Calibration Labels for machine tools, heavy machines, pharmaceuticals, automobiles, and other industries