Polycarbonate stickers and labels are a popular choice for a variety of applications due to their durability and versatility. Here’s a breakdown of what makes them a good option:

What are polycarbonate stickers and labels?

- Material: Made from polycarbonate, a strong and lightweight plastic.

- Durability: Resistant to scratches, chemicals, and extreme temperatures.

- Versatility: Can be used for a wide range of purposes.

Benefits of using polycarbonate stickers and labels:

- Long-lasting: They can withstand harsh conditions and elements, making them a cost-effective choice.

- High-quality: Offer excellent color reproduction and can be easily embossed for a professional look.

- Versatile: Can be used on various surfaces and in different environments.

- Customizable: Available in various thicknesses, finishes, and adhesive options to meet specific needs.

Common applications:

- Industrial equipment: Used for labeling machinery, control panels, and safety warnings.

- Electronics: Ideal for product identification, branding, and regulatory information.

- Automotive: Can be found on dashboards, interior components, and exterior trim.

- Outdoor applications: Weather-resistant and UV-resistant options are available for outdoor use.

Things to consider:

- Cost: Polycarbonate stickers and labels may be slightly more expensive than other options, but their durability often makes them a worthwhile investment.

- Printing: Requires specialized printing techniques to ensure high-quality results.

Where to find them:

- Label manufacturers: Many companies specialize in producing custom polycarbonate stickers and labels.

- Online retailers: A wide variety of options can be found online, often with customization options.

Overall, polycarbonate stickers and labels are a reliable choice for applications that demand durability, versatility, and a professional appearance.

You’re right to ask about usages! Polycarbonate stickers and labels are incredibly versatile. Here’s a breakdown of their common applications, expanding on what I mentioned before:

1. Industrial Equipment and Machinery:

- Safety labels: Warning labels for hazardous materials, machine operation instructions, and safety precautions. Polycarbonate’s resistance to chemicals and abrasion makes it ideal for these demanding environments.

- Asset tracking: Durable labels for identifying equipment, tools, and inventory. They can withstand harsh conditions and maintain legibility.

- Control panels: Clear and long-lasting labels for buttons, switches, and displays on machinery.

2. Electronics:

- Product identification: Branding labels, model numbers, and regulatory information on electronic devices. Polycarbonate offers a professional look and resists scratches.

- Serial number labels: Tamper-proof labels for tracking electronics and preventing counterfeiting.

- Keyboard overlays: Durable and clear overlays for keyboards and keypads, protecting them from wear and tear.

3. Automotive and Heavy Machinery:

- Interior labels: Labels for dashboards, controls, and other interior components. Polycarbonate can withstand temperature fluctuations and resist fading.

- Exterior labels: Weather-resistant labels for vehicle branding, model identification, and warning labels.

- Engine compartment labels: Labels that can withstand high temperatures, oil, and other harsh chemicals found in engine compartments.

4. Outdoor Applications:

- Signage: Durable labels for outdoor signs, directional markers, and informational displays. UV-resistant polycarbonate ensures long-lasting visibility.

- Warning labels: Weatherproof labels for outdoor equipment, fences, and hazardous areas.

- Promotional stickers: Eye-catching and durable stickers for outdoor advertising and branding.

5. Other Industries:

- Medical devices: Labels for medical equipment, instruments, and supplies. Polycarbonate can be made to meet strict hygiene and regulatory requirements.

- Aerospace: Labels for aircraft interiors, equipment, and components. Polycarbonate’s lightweight and durable properties are valuable in this industry.

- Consumer goods: Labels for appliances, tools, and other consumer products. Polycarbonate adds a touch of quality and durability.

Key Factors Driving These Usages:

- Durability: Resistance to scratches, chemicals, extreme temperatures, and UV exposure.

- Long-lasting: Polycarbonate labels maintain their appearance and functionality over time.

- Versatility: Can be customized in various shapes, sizes, and finishes.

- High-quality: Offers excellent printability and clarity for professional-looking labels.

# 139, KIADB Indl Area, 4th Phase, Bommasandra, Hosur-Jigani Link Road Bangalore, India 560099

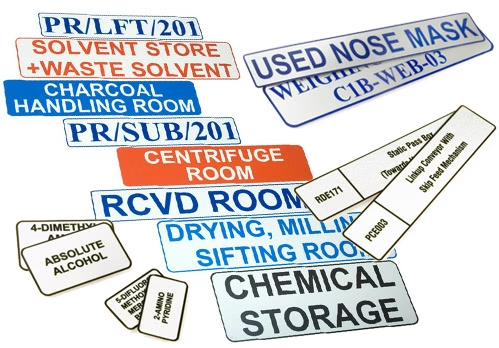

Pharma/On-site Signage

For Enquires:

- enquiry@kinelectro.com

- +919686466322 +919980454999