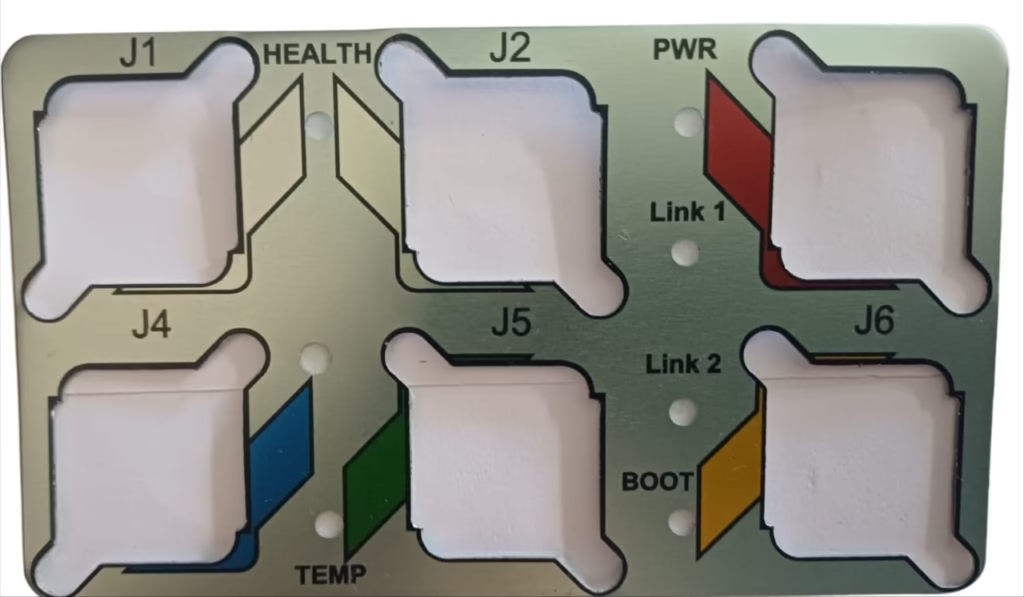

Aluminium Name Plate with CNC cut

Aluminium name plate with CNC cut

Aluminium name plate with cnc cut Aluminium name plates with CNC (Computer Numerical Control) cutting are a popular choice in industries that require high precision, durability, and a professional finish. These nameplates are used across sectors like manufacturing, automotive, electrical, aerospace, marine, and more due to their superior appearance and functionality.

What Are Aluminium Name Plates with CNC Cut?

These are identification tags, plates, or labels made from aluminium that are precisely cut using CNC machines. CNC cutting involves the use of automated machines controlled by computer software to mill, engrave, or shape aluminium sheets into desired sizes and patterns. The process allows intricate detailing, consistent results, and smooth edges.

Key Features

High Precision:

CNC machines can cut aluminium with micron-level accuracy, allowing for complex designs and tight tolerances.Smooth Edges and Clean Finish:

Unlike manual or die-cutting methods, CNC produces burr-free, uniform edges without the need for secondary finishing.Customization:

CNC technology allows easy customization of shapes, holes, slots, logos, and text as per user requirements.Durability:

Aluminium is corrosion-resistant, weatherproof, and long-lasting, making it ideal for both indoor and outdoor use.Aesthetic Appeal:

With CNC, you can achieve detailed logo engravings, embossed text, and design elements that enhance the overall look of the nameplate.

Advantages of CNC-Cut Aluminium Name Plates

Repeatability: Perfect for bulk orders; every piece looks exactly the same.

Material Efficiency: Less wastage due to precision cutting.

Fast Turnaround: Automated process ensures speed.

Compatibility: Suitable for barcodes, QR codes, and laser-marked information.

Environmentally Friendly: Aluminium is recyclable, and CNC processes have minimal waste.

Why Choose CNC Cutting for Aluminium Name Plates?

CNC cutting brings precision, reliability, and versatility to the nameplate manufacturing process. Whether you need a small, intricate tag for a control panel or a large branding plate for industrial machinery, CNC ensures the best possible output with minimal error.

Kinelectro Lines – Aluminium CNC Name Plate Manufacturer

If you’re looking for custom aluminium name plates with CNC cut, Kinelectro Lines India Pvt. Ltd. offers tailored solutions with high-quality materials, fast delivery, and competitive pricing. From simple identification tags to complex industrial labeling, their CNC capabilities ensure excellence in every cut.

CNC (Computer Numerical Control) cutting on aluminium is a widely adopted manufacturing process used to shape, engrave, or mill aluminium sheets or blocks with high precision and efficiency. Aluminium, being lightweight, durable, and corrosion-resistant, is an ideal material for CNC machining and is commonly used across industries like aerospace, automotive, electronics, and signage.

Types of CNC Operations on Aluminium

CNC Milling – Used to remove material and shape aluminium blocks or sheets.

CNC Engraving – Ideal for logos, serial numbers, and detailed designs on nameplates or components.

CNC Routing – Used primarily for cutting out shapes, panels, and parts from flat aluminium sheets.

CNC Drilling – Accurate and uniform hole-making in aluminium parts.

CNC Cutting Process – Step-by-Step

Design:

Create a design file using CAD (Computer-Aided Design) software. This includes dimensions, shapes, holes, and engraving details.CAM Programming:

Convert the design into machine instructions using CAM (Computer-Aided Manufacturing) software.Machine Setup:

Aluminium workpiece is clamped onto the CNC machine bed. Appropriate cutting tools are loaded.Cutting/Engraving:

The CNC machine executes the program, cutting or engraving the aluminium precisely.Finishing:

Deburring, polishing, anodizing, or coating is done for a clean and finished look.