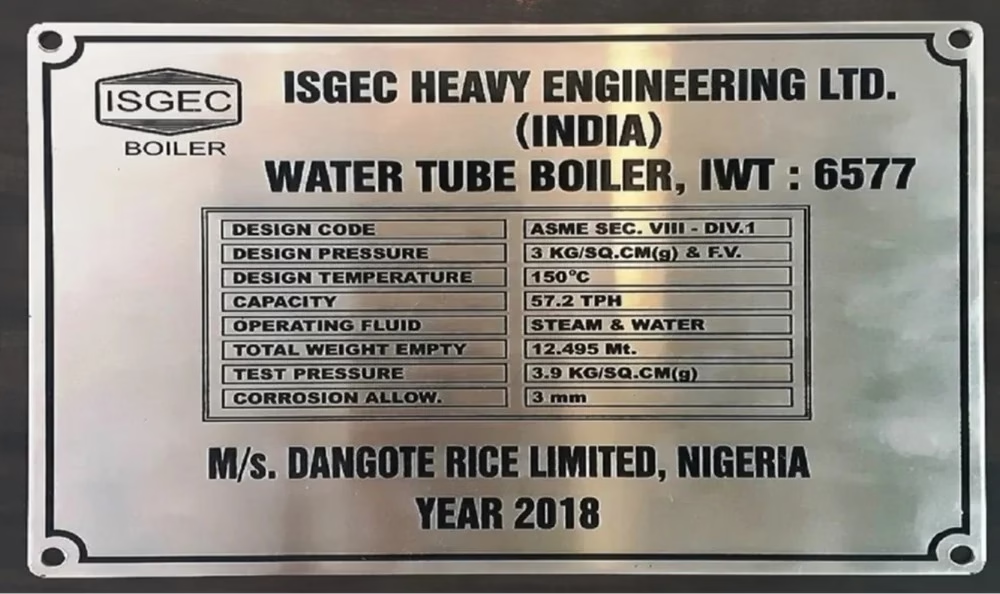

Boiler nameplates are small metal plates that contain essential information about a boiler. They are typically attached to the front of the boiler and must be easily accessible and visible.

Boiler Nameplates: An Essential Component for Boiler Identification and Safety

Boiler nameplates are crucial components for identifying the specifications, features, and operational limits of a boiler. Affixed to the exterior of the boiler, these nameplates provide essential information that helps ensure the boiler is operated safely and efficiently. In this article, we will delve into the significance of boiler nameplates, what details they contain, and why they are necessary for proper boiler operation and maintenance.

What is a Boiler Nameplate?

A boiler nameplate is a metal or durable material plate attached to the surface of a boiler. It contains a variety of information about the boiler’s construction, specifications, and operational limits. These nameplates are required by industry standards and regulations to ensure that operators are aware of the boiler’s performance characteristics, capacity, and any relevant safety precautions. The nameplate serves as a reference point for maintenance professionals, engineers, and regulatory authorities, helping them make informed decisions about the equipment.

Information Found on a Boiler Nameplate

The information on a boiler nameplate can vary depending on the manufacturer and the specific model of the boiler. However, most nameplates include several key elements, all of which play an important role in ensuring safe and efficient operation:

- Manufacturer Information

This section includes the name of the boiler’s manufacturer, their location, and often a contact number or website. This is useful for identifying the manufacturer in case the boiler needs to be serviced or replaced. It also ensures that the correct support and documentation can be obtained.

- Model and Serial Number

The model number helps identify the specific boiler design, while the serial number is a unique identifier for each individual unit. This allows for traceability in terms of repairs, inspections, and warranty claims. If a recall or safety alert is issued, having a specific serial number helps pinpoint the affected units.

- Boiler Capacity

This refers to the amount of steam or hot water the boiler can produce, often expressed in pounds of steam per hour (lbs/hr) or horsepower (HP). It is an essential figure for understanding the size and power of the boiler. For instance, a high-capacity industrial boiler will have a much higher output than a residential or small commercial unit.

- Pressure Rating

The pressure rating indicates the maximum allowable working pressure (MAWP) that the boiler can safely handle. Exceeding this pressure can result in a catastrophic failure, so it is vital that operators are fully aware of this limit. The pressure is typically specified in pounds per square inch (psi).

- Temperature Range

The temperature range refers to the highest and lowest temperatures the boiler is designed to handle. It is closely related to the pressure rating and should never be exceeded to avoid accidents such as overheating or thermal stress on the system.

- Fuel Type

Boilers can operate on a variety of fuels, including natural gas, oil, coal, or biomass. The fuel type listed on the nameplate indicates the appropriate fuel for the boiler, helping ensure that the right material is used to operate the system. Using the wrong fuel can lead to inefficient operation, damage to the boiler, or even a hazardous situation.

- Year of Manufacture

This is the date when the boiler was constructed and is important for determining the boiler’s age. Older boilers may be more prone to wear and require more frequent inspections or even replacement. The year of manufacture also helps in identifying when the boiler was built to comply with relevant regulations or codes of practice.

- Efficiency Rating

Some modern boilers come with an efficiency rating that indicates how effectively they convert fuel into usable energy. Higher efficiency typically means lower fuel consumption for the same heat output, which can significantly reduce operational costs over time.

- Safety Features

The nameplate may also include details about built-in safety features, such as safety valves, pressure relief devices, and other critical safety mechanisms. These are essential for preventing overpressure situations and ensuring that the boiler operates within safe limits.

- Other Regulatory Information

Many nameplates will include certifications or compliance marks that confirm the boiler meets relevant national or international standards. For example, boilers may have a mark showing compliance with ASME (American Society of Mechanical Engineers) standards or other regulatory agencies, ensuring that the equipment has been built to meet safety and performance requirements.

Importance of Boiler Nameplates

- Safety

The primary reason for boiler nameplates is to ensure safety. Boilers operate under high pressure and temperature, and failure to adhere to the specifications can lead to accidents like explosions, fires, or system failures. By clearly outlining the operational limits, the nameplate helps operators understand how to safely run the boiler and what to do in the event of a malfunction.

- Regulatory Compliance

Boilers are subject to strict regulations and codes, both for installation and operation. A properly marked nameplate ensures that the boiler meets these requirements. Regulatory authorities will often refer to the nameplate during inspections to ensure compliance with safety standards.

- Maintenance and Troubleshooting

The nameplate is an invaluable resource for technicians who need to maintain or repair the boiler. It provides quick access to key data about the boiler’s operation, making it easier to troubleshoot issues and order the correct replacement parts. Without a nameplate, identifying the right specifications would be difficult and time-consuming.

- Warranty and Service

In case the boiler experiences issues, the nameplate’s serial number and manufacturer details will help ensure that warranty services can be properly accessed. Manufacturers often require the serial number for troubleshooting, claims, and service records.