Nameplates manufacturer – customized design as per your design

In a world saturated with mass-produced goods, the humble nameplate is a testament to individuality, professionalism, and functionality. Often overlooked, these seemingly simple objects play a crucial role in shaping our environments, from the doors of our homes to the intricate machinery of industrial complexes. Behind each polished surface and precisely etched character lies a complex manufacturing process, driven by skilled artisans and cutting-edge technology.

Nameplate manufacturers are the unsung heroes of visual communication, transforming raw materials into tangible markers of identity. Their work spans a vast spectrum, encompassing residential, commercial, and industrial applications. From the elegant brass plates adorning Victorian homes to the robust stainless steel labels identifying critical equipment, nameplates serve as both functional identifiers and aesthetic enhancements.

The Importance of Quality and Customization:

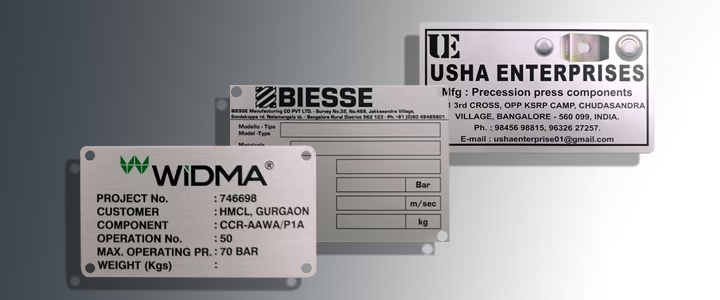

In a competitive market, nameplate manufacturers differentiate themselves through quality and customization. Quality extends beyond the materials and manufacturing process, encompassing the attention to detail, precision, and durability of the finished product.

Customization is equally crucial. Clients seek nameplates that reflect their unique identities and requirements. Manufacturers must be able to accommodate a wide range of specifications, from custom shapes and sizes to intricate graphics and personalized fonts

The Diverse Applications of Nameplates:

- Commercial: Businesses utilize nameplates for office signage, directional markers, and product labeling, reinforcing brand identity and facilitating navigation.

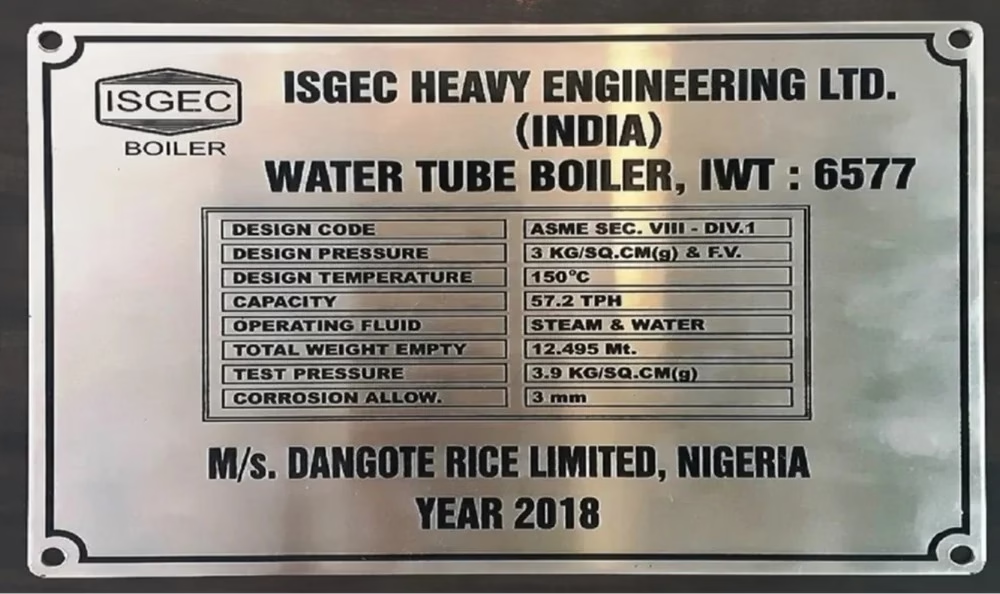

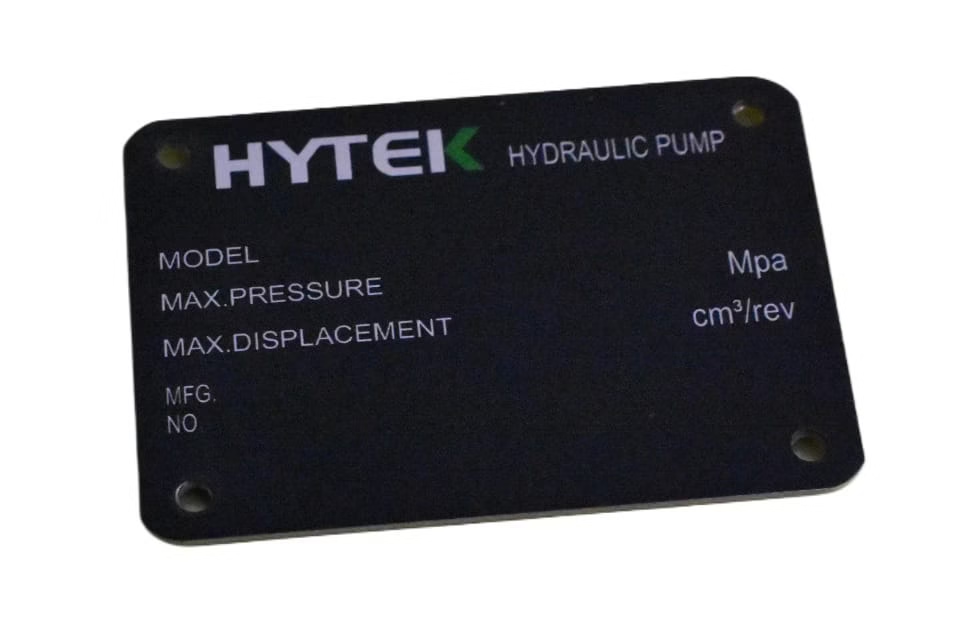

- Industrial: In industrial settings, nameplates serve as critical identifiers for machinery, equipment, and pipelines, ensuring safety and operational efficiency.

- Institutional: Schools, hospitals, and government buildings employ nameplates for wayfinding, identification, and information dissemination.

- Awards and Recognition: Nameplates personalize trophies, plaques, and awards, commemorating achievements and milestones.

- Product Identification: Manufacturers use nameplates to label their products, providing essential information such as model numbers, serial numbers, and safety warnings

The Silent Architects of Identity: A Deep Dive into Nameplate Manufacturing

In a world saturated with mass-produced goods, the humble nameplate stands as a testament to individuality, professionalism, and functionality. Often overlooked, these seemingly simple objects play a crucial role in shaping our environments, from the doors of our homes to the intricate machinery of industrial complexes. Behind each polished surface and precisely etched character lies a complex manufacturing process, driven by skilled artisans and cutting-edge technology.

Nameplate manufacturers are the unsung heroes of visual communication, transforming raw materials into tangible markers of identity. Their work spans a vast spectrum, encompassing residential, commercial, and industrial applications. From the elegant brass plates adorning Victorian homes to the robust stainless steel labels identifying critical equipment, nameplates serve as both functional identifiers and aesthetic enhancements.

The Craft and the Technology:

The journey of a nameplate begins with design. Clients often provide specific requirements, including dimensions, materials, fonts, and graphics. Manufacturers, however, possess the expertise to guide these choices, ensuring the final product aligns with both aesthetic preferences and functional needs.

The selection of materials is paramount. Traditional materials like brass, bronze, and aluminum offer timeless elegance and durability. Stainless steel, known for its corrosion resistance, is favored in industrial settings. Modern materials like acrylic and laminate offer versatility in design and cost-effectiveness.

Once the design and materials are finalized, the manufacturing process begins. Several techniques are employed, each offering unique characteristics:

- Engraving: This traditional method involves cutting into the material using a rotating tool. Laser engraving, a modern variant, utilizes a focused beam of light for precise and intricate designs.

- Etching: This chemical process involves selectively removing material using acid, resulting in deeply recessed designs. Etching is particularly suitable for intricate patterns and fine details.

- Printing: Screen printing, digital printing, and UV printing allow for vibrant color reproduction and complex graphics on various surfaces.

- CNC Machining: Computer Numerical Control (CNC) machining utilizes automated tools to precisely cut and shape materials, enabling the creation of complex 3D nameplates.

- Casting: For metals like brass and bronze, casting involves pouring molten metal into molds, creating robust and detailed nameplates.

The choice of technique depends on the desired aesthetic, material, and production volume. For small batches and personalized designs, engraving and etching may be preferred. For high-volume production and complex graphics, printing and CNC machining offer greater efficiency.

The Importance of Quality and Customization:

In a competitive market, nameplate manufacturers differentiate themselves through quality and customization. Quality extends beyond the materials and manufacturing process, encompassing the attention to detail, precision, and durability of the finished product.

Customization is equally crucial. Clients seek nameplates that reflect their unique identities and requirements. Manufacturers must be able to accommodate a wide range of specifications, from custom shapes and sizes to intricate graphics and personalized fonts.

The Diverse Applications of Nameplates:

The versatility of nameplates is evident in their diverse applications:

- Residential: Nameplates adorning homes, mailboxes, and doorbells add a touch of personality and enhance curb appeal.

- Commercial: Businesses utilize nameplates for office signage, directional markers, and product labeling, reinforcing brand identity and facilitating navigation.

- Industrial: In industrial settings, nameplates serve as critical identifiers for machinery, equipment, and pipelines, ensuring safety and operational efficiency.

- Institutional: Schools, hospitals, and government buildings employ nameplates for wayfinding, identification, and information dissemination.

- Awards and Recognition: Nameplates are used to personalize trophies, plaques, and awards, commemorating achievements and milestones.

- Product Identification: Manufacturers use nameplates to label their products, providing essential information such as model numbers, serial numbers, and safety warnings.

The Future of Nameplate Manufacturing:

The nameplate manufacturing industry is constantly evolving, driven by technological advancements and changing consumer preferences. Digital printing, laser engraving, and CNC machining are becoming increasingly sophisticated, enabling the creation of more intricate and customized designs.

Sustainability is also gaining prominence. Manufacturers are exploring eco-friendly materials and processes, reducing their environmental impact.

The rise of e-commerce has expanded the reach of nameplate manufacturers, allowing them to cater to a global clientele. Online platforms enable clients to design and order custom nameplates from the comfort of their homes or offices.

As our world becomes increasingly interconnected and information-driven, the importance of clear and effective visual communication will only grow. Nameplate manufacturers, with their blend of craftsmanship and technology, will continue to play a vital role in shaping our environments, providing the silent architecture of identity that guides, informs, and enhances our daily lives. From the personal touch of a home address to the vital information on industrial equipment, the nameplate, carefully manufactured, will continue its essential role.

We custom manufacture for Industrial applications Anodized Aluminum and Polymer based Name Plates, Fascia Panels, Mimic Panels , Overlays, Decals, Safety Signage, Calibration Labels, Asset Management Labels, and lots more.

At Kinelectro Lines, we blend decades of experience with cutting-edge technology to create custom industrial signage that exceeds expectations. Our team of skilled professionals ensures that every project, from concept to installation, is executed with precision and attention to detail.

# 139, KIADB Indl Area, 4th Phase, Bommasandra, Hosur-Jigani Link Road Bangalore, India 560099

Machine & Equipment’s

Pharma/On-site Signage

For Enquires:

- enquiry@kinelectro.com

- +919686466322 +919980454999