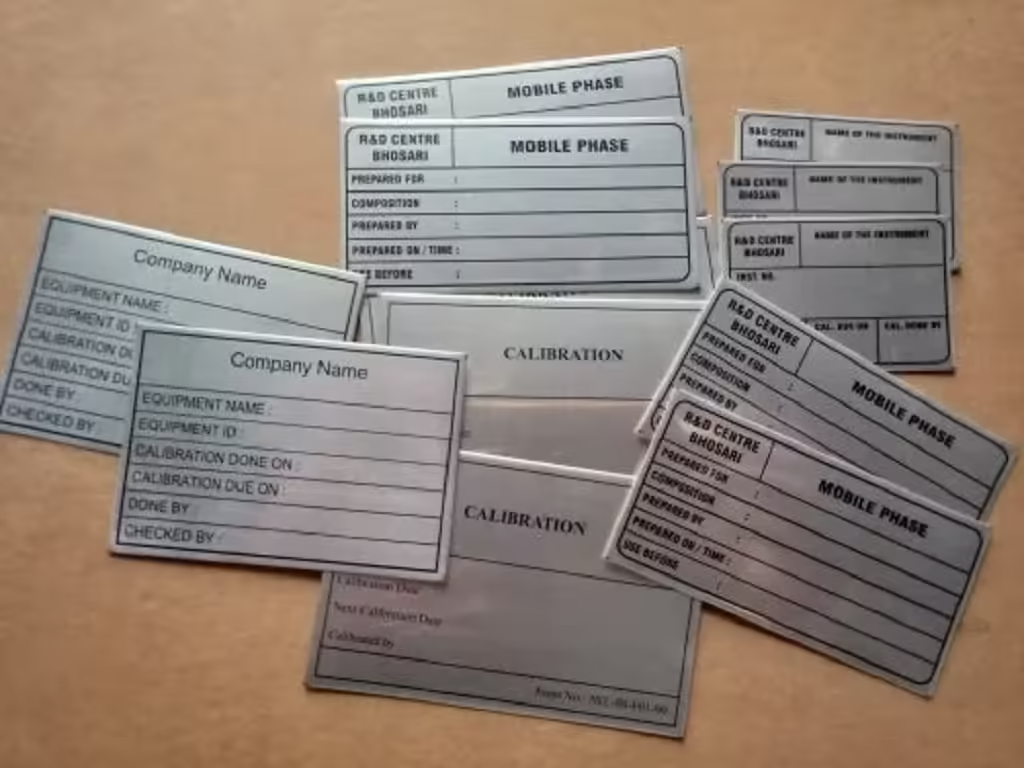

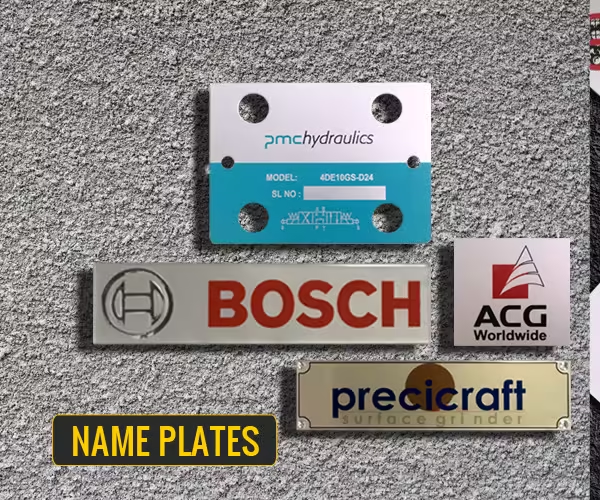

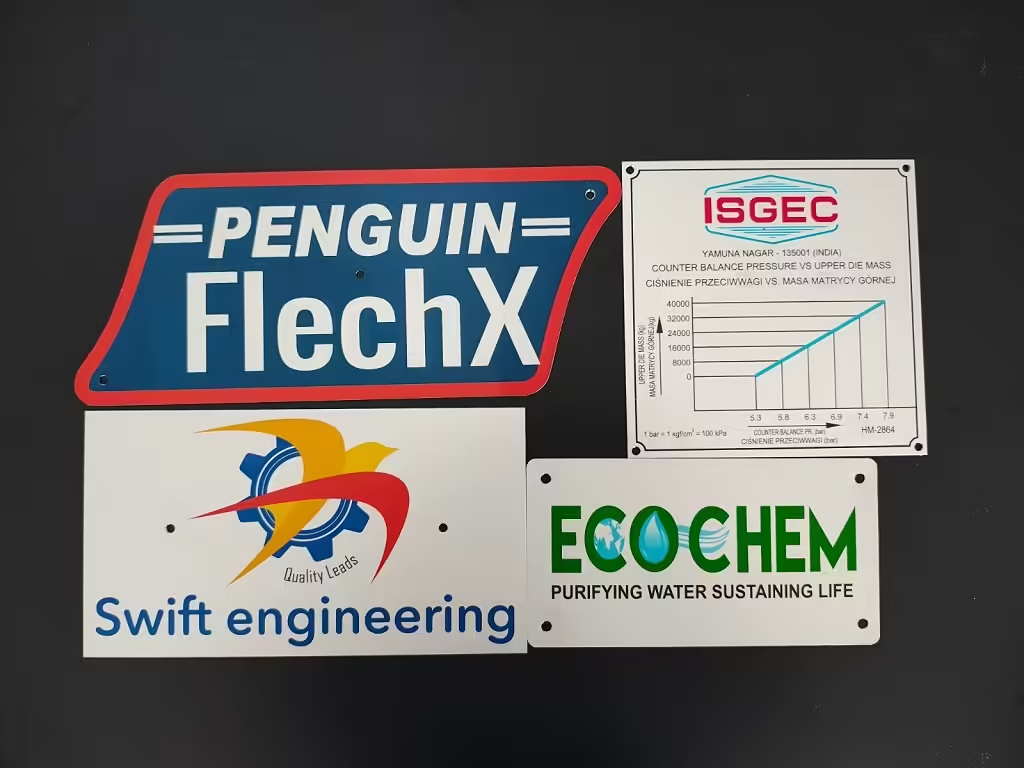

Aluminium Name Plates and Labels: Essential Information for Industrial Applications

In the industrial world, nameplates and labels are more than just identifiers; they play a crucial role in the safety, efficiency, and organization of operations. Aluminium nameplates, in particular, have become a go-to solution for industries requiring durable and customizable labels. This article will explore the various types of aluminium nameplates and labels, their applications, and why Kinelectro stands out as a leading supplier in the industry.

What are Aluminium Nameplates and Labels?

Aluminium name plates and labels are designed for industrial applications where durability and long-lasting performance are essential. These products are used to display critical information such as brand names, model numbers, safety instructions, or warning signs. While the terms “nameplates” and “labels” are often used interchangeably, nameplates typically refer to larger, more permanent fixtures, while labels are often smaller and can be more easily replaced or altered.

Advantages of Aluminium Nameplates

When it comes to nameplates and labels, aluminium is a material of choice for many industries. Here’s why:

- Durability: Aluminium is naturally resistant to corrosion, rust, and wear. This makes it perfect for harsh environments where metal or plastic labels might fail quickly.

- Cost-Effective: Although aluminium may cost more upfront compared to other materials, its longevity ensures that businesses save money over time on replacements and maintenance.

- Versatility: Aluminium nameplates and labels can be customized in various shapes, sizes, and finishes to suit the needs of any application, whether it’s for heavy machinery or control panels.

Applications of Aluminium Nameplates and Labels

Aluminium nameplates and labels are used in a variety of industries. Some key applications include:

- Machinery Identification: Nameplates help identify and brand industrial machinery, motor pumps, and control panels, making maintenance easier and more organized.

- Safety Labels: Labels provide essential safety instructions or warnings in factories and production facilities, helping to prevent accidents.

Aluminium Industrial Nameplates

Aluminium industrial name plates are essential for identification and brand recognition in manufacturing plants, assembly lines, and industrial machinery. These plates are often customized to include the company’s logo, machine specifications, and regulatory compliance information. Aluminium’s resistance to corrosion and harsh weather conditions makes it the perfect material for these demanding environments.

Features of Aluminium Industrial Nameplates

- Resistant to extreme temperatures and outdoor conditions

- Customizable with various finishes (anodized, etched, etc.)

- Offers a professional and durable solution for industrial branding

Types of Aluminium Nameplates

Anodized Aluminium Nameplates

Anodizing is an electrochemical process that enhances the natural properties of aluminium. Anodized aluminium nameplates are highly resistant to corrosion, scratching, and fading, which makes them perfect for outdoor applications or environments with high exposure to chemicals.

Common Uses:

- Control panels

- Outdoor signage

- Harsh industrial settings

Motor Pumps Aluminium Labels

Motor pumps often require labels that can withstand constant wear, oil exposure, and extreme heat. Aluminium labels used in motor pumps are typically highly durable, providing critical information like part numbers, specifications, and safety warnings.

Control Panel Labels

Control panels in industrial settings need clearly visible and durable labels to ensure safety and proper functionality. Aluminium control panel labels are resistant to high temperatures, chemicals, and wear, making them ideal for use in power plants, factories, and manufacturing sites.

Industrial Barcode Tags

Barcode tags are crucial for inventory and asset tracking in industrial environments. Aluminium barcode tags are especially valuable because they resist corrosion and remain readable over long periods, even in harsh conditions. These tags can withstand exposure to UV rays, chemicals, and abrasion, making them ideal for tracking machinery, parts, and tools.

How Aluminium Nameplates are Made

Aluminium nameplates and labels can be produced through several methods, including:

- Engraving: A mechanical process that involves carving text and designs into the aluminium surface.

- Etching: A chemical process that uses acid to create designs on the surface of the metal.

- Anodizing: An electrochemical process that creates a protective oxide layer on the aluminium for enhanced durability.

Customisation options for aluminium nameplates include various finishes, shapes, sizes, and colors to suit any specific requirement.

Choosing the Right Aluminium Nameplate for Your Needs

When selecting an aluminium nameplate or label, consider the following factors:

- Environmental Conditions: Will the label be exposed to heat, chemicals, or outdoor elements?

- Durability Requirements: Does the label need to withstand frequent handling or abrasion?

- Customization: Do you need a specific design or logo on the label?

- Size and Placement: Ensure the label fits the space and is easy to read.

Why Kinelectro?

Kinelectro is a leading provider of aluminium nameplates and labels, known for its expertise in producing high-quality products that meet the specific needs of industries like manufacturing, engineering, and electronics.

What Sets Kinelectro Apart?

- Expertise in crafting durable, custom labels and nameplates

- Wide range of options for industries requiring unique designs and applications

- Fast turnaround times and high-quality assurance

Benefits of Partnering with Kinelectro for Aluminium Labels and Nameplates

- Quality Assurance: Kinelectro uses state-of-the-art technology and materials to ensure that every label and nameplate meets the highest standards.

- Customization Options: Whether you need anodized, etched, or printed labels, Kinelectro offers tailored solutions.

- Reliability: With years of industry experience, Kinelectro is a trusted partner for all your industrial label needs.

Maintenance and Care for Aluminium Nameplates and Labels

To ensure the longevity of your aluminium nameplates and labels, regular maintenance is key. Here are a few tips:

- Clean Regularly: Use a mild detergent and soft cloth to wipe away dust and debris.

- Check for Damage: Regularly inspect labels for wear or fading, especially in high-traffic areas.

- Protect from Harsh Chemicals: Avoid exposing labels to harsh chemicals that can damage the surface.

Conclusion

Aluminium nameplates and labels are an essential component in many industrial settings. Whether you are identifying machinery, enhancing branding, or ensuring safety, aluminium labels offer the durability and flexibility needed for a variety of applications. With Kinelectro’s expertise in providing customized solutions, you can be assured of high-quality, long-lasting nameplates and labels for all your industrial needs.

FAQs

What is the difference between an aluminium nameplate and an aluminium label?

- A nameplate is typically larger and more permanent, while a label is smaller and more flexible for temporary or changeable information.

Can aluminium nameplates be used outdoors?

- Yes, aluminium is highly resistant to outdoor conditions, including UV rays, moisture, and extreme temperatures, making it perfect for outdoor applications.

How long do aluminium labels last?

- Aluminium labels can last for many years, especially when treated with processes like anodizing, making them highly durable in harsh environments.

Are aluminium labels customizable?

- Yes, aluminium labels can be customized in terms of size, shape, color, and finish to suit specific industrial needs.

Why choose anodized aluminium for industrial labels?

- Anodized aluminium offers enhanced durability and resistance to corrosion, fading, and scratching, making it ideal for industries that require long-lasting labels in tough conditions.

# 139, KIADB Indl Area, 4th Phase, Bommasandra, Hosur-Jigani Link Road Bangalore, India 560099

Machine & Equipment’s

Pharma/On-site Signage

For Enquires:

- enquiry@kinelectro.com

- +919686466322 +919980454999