Machinery nameplates play a vital role in industrial and manufacturing environments. These durable, informative tags provide essential details about a machine’s specifications, safety guidelines, and regulatory compliance. More than just a label, a nameplate is often a legal requirement and a key component for operational efficiency and safety.

In this comprehensive guide, we’ll explore machinery nameplates, their importance, types, materials used, customization options, and compliance considerations.

What Are Machinery Nameplates?

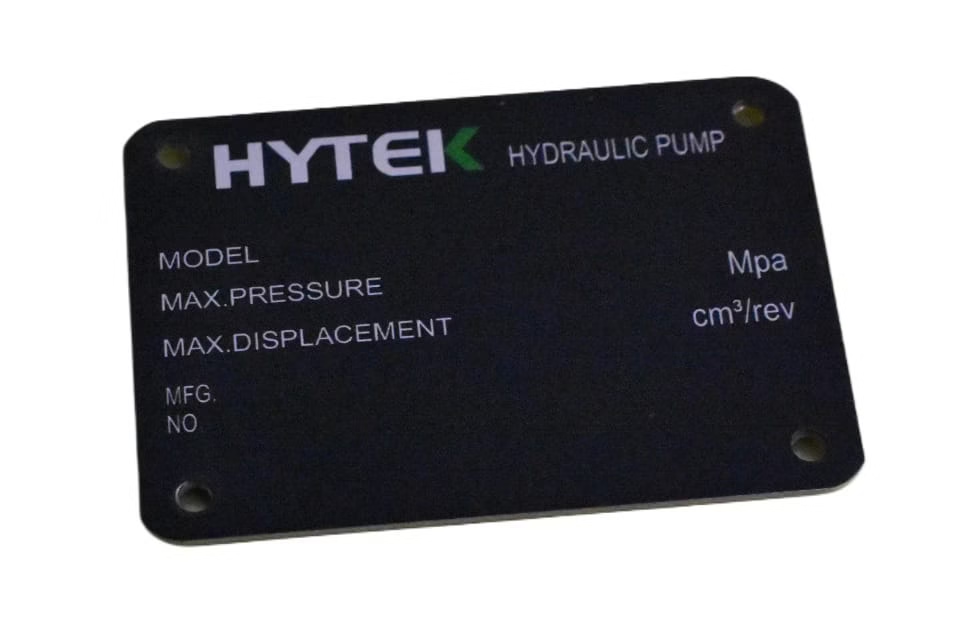

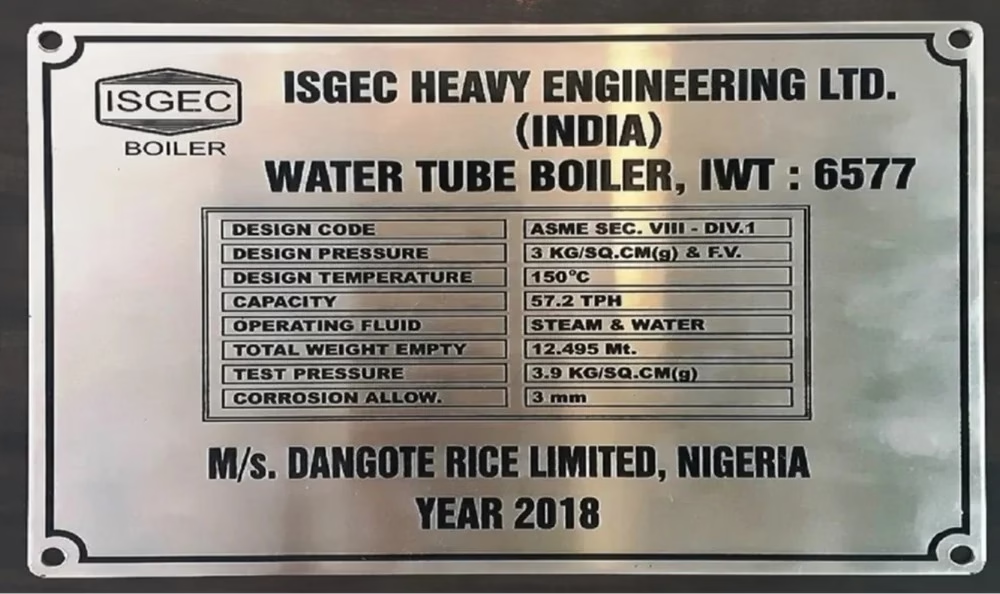

Machinery nameplates are identification plates that are permanently attached to industrial equipment. They typically contain engraved, etched, or printed information related to the machine, including:

- Manufacturer’s name and logo

- Model number

- Serial number

- Power requirements (voltage, frequency, current)

- Load capacity

- Date of manufacture

- Country of origin

- Safety warnings and symbols

- Certification logos (e.g., CE, UL, CSA)

These plates are built to withstand harsh environments, including exposure to heat, moisture, chemicals, abrasion, and UV rays.

Why Are Nameplates Important?

1. Regulatory Compliance

Many industrial machines are governed by safety and compliance regulations. Nameplates ensure that a machine meets standards set by organizations such as OSHA (Occupational Safety and Health Administration), ANSI (American National Standards Institute), and the IEC (International Electrotechnical Commission). Missing or incorrect nameplates can lead to fines, operational delays, or legal issues.

2. Safety

A nameplate communicates important safety information, such as maximum operating parameters and electrical warnings. This helps operators use the machine safely and reduces the risk of accidents or injuries.

3. Maintenance and Servicing

Technicians rely on the information provided by nameplates to service machinery correctly. The model number, serial number, and power specs are essential for diagnostics, ordering parts, or scheduling maintenance.

4. Asset Tracking and Inventory

In large facilities, keeping track of hundreds or thousands of machines can be challenging. Nameplates assist in identifying each piece of equipment quickly and accurately, aiding in inventory management and asset tracking.

Common Materials Used in Machinery Nameplates

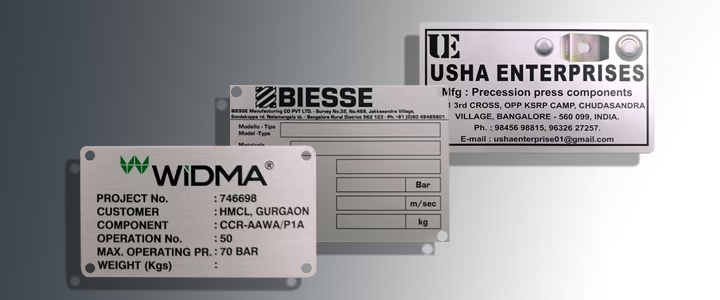

The choice of material for a nameplate depends on the environment in which the machinery operates. Common materials include:

• Aluminum

Lightweight, corrosion-resistant, and durable, aluminum is one of the most widely used materials for nameplates. It can be anodized for added protection and can withstand outdoor conditions.

• Stainless Steel

Highly durable and resistant to heat and chemicals, stainless steel is ideal for heavy-duty and high-temperature applications. It’s common in the food, chemical, and pharmaceutical industries.

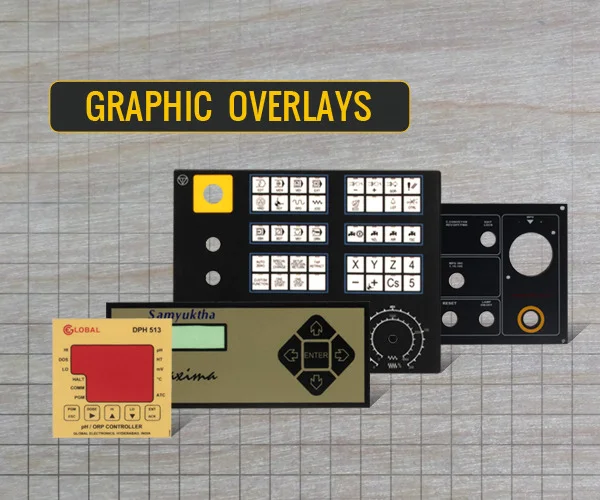

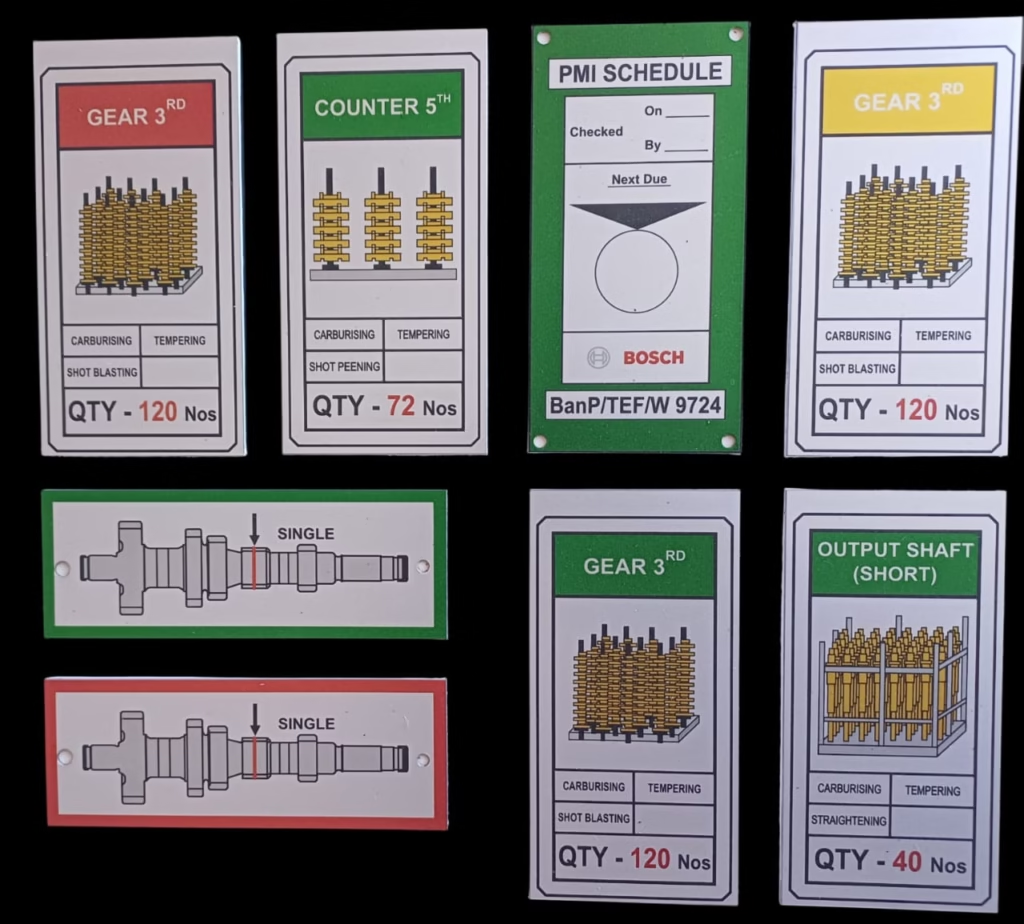

• Polycarbonate and Polyester

These plastic materials are used for machines that don’t require metal plates. They’re lightweight, flexible, and can be printed with vibrant colors and complex graphics. Often laminated for added durability.

Nameplate Manufacturing Methods

The production process of a nameplate depends on the material and the desired durability. Common methods include:

- Engraving – Ideal for metal nameplates, engraving creates long-lasting and readable impressions.

- Etching – Chemical etching is used for precision and durability, especially on stainless steel or aluminum.

- Screen Printing – Used for high-volume production with detailed graphics, though less durable than engraving.

- Laser Marking – A high-precision method that works well on metals and plastics.

- Digital Printing – Suitable for colorful, custom designs on plastic or anodized aluminum.

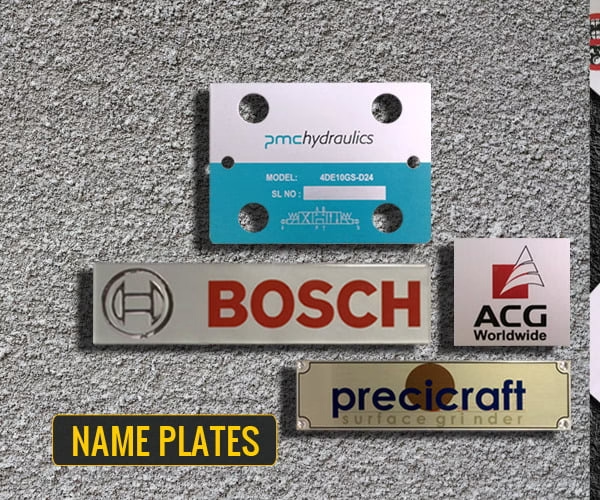

Applications of Machinery Nameplates

Machinery nameplates are used across various industries:

- Manufacturing and Industrial Equipment: For heavy machinery, conveyors, CNC machines, and presses.

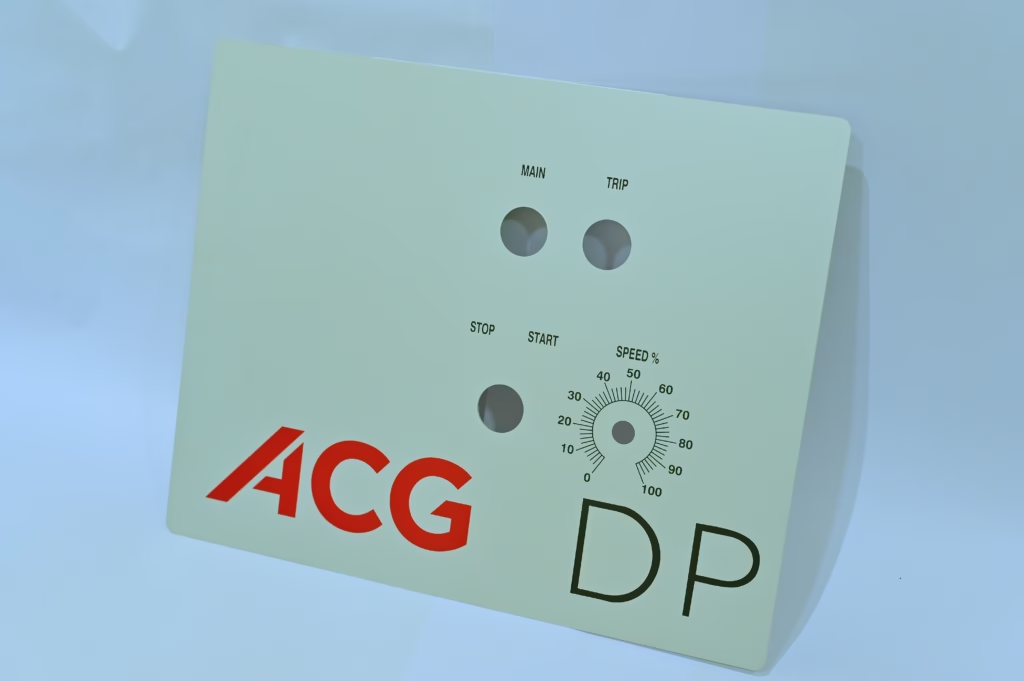

- Electrical Equipment: Transformers, generators, motors, and control panels.

- Construction Machinery: Cranes, bulldozers, excavators.

- Medical Equipment: To identify models and comply with FDA regulations.

- Aerospace and Defense: For labeling aircraft components and defense equipment with precision and traceability.

- Energy Sector: Wind turbines, oil rigs, and solar power systems.

Customization Options

Machinery nameplates can be customized in a variety of ways to meet specific business needs and industry standards:

- Barcodes and QR Codes: Enable quick digital tracking and inventory management.

- Color Coding: Helps distinguish between departments, functions, or machine types.

- Logos and Branding: Incorporate company branding while maintaining regulatory compliance.

- Variable Data Printing: Allows each nameplate to display unique data like serial numbers or manufacturing dates.

Compliance and Certification Standards

A properly designed nameplate must comply with various international and regional regulations. Depending on the industry and country, compliance may include:

- CE Marking (EU) – Indicates conformity with health, safety, and environmental protection standards.

- UL Certification (US/Canada) – Certifies electrical equipment safety.

- CSA (Canadian Standards Association) – Ensures safety compliance in Canada.

- RoHS/REACH – European standards for hazardous materials and environmental safety.

- ISO 9001 – Quality management certification for manufacturers of nameplates.

Always consult relevant regulatory bodies when designing nameplates to ensure proper labeling.

Selecting the Right Nameplate Manufacturer

Choosing a reliable nameplate supplier is crucial. Look for manufacturers that offer:

- Customization and design assistance

- Durable, high-quality materials

- Compliance with international standards

- Experience in your specific industry

- Fast turnaround and flexible ordering quantities

Working with a supplier that understands your industry’s requirements ensures the nameplates will meet both functional and legal expectations.

Conclusion

Machinery nameplates are far more than just identification tags. They’re essential for safety, compliance, maintenance, and operational efficiency. Whether you’re managing a factory floor, constructing a wind farm, or running a medical device company, high-quality, compliant nameplates can protect your assets, your people, and your business.

Investing in the right nameplate today can help prevent serious problems tomorrow. Be sure to choose a material and design that suits your equipment’s environment, and always ensure compliance with applicable industry regulations. From laser-engraved stainless steel to full-color polycarbonate labels, there’s a nameplate solution for every machine and every industry.