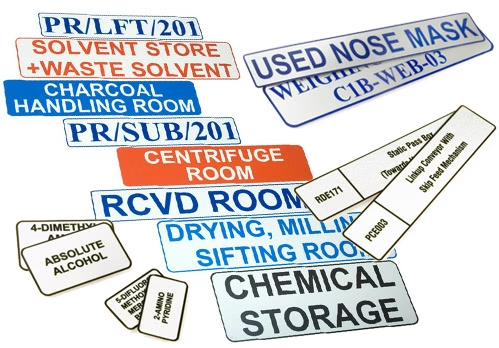

Screen printed aluminum nameplates

Screen printed aluminum nameplates are commonly used in industrial applications due to their durability, resistance to harsh environments, and ability to withstand wear and tear. They are perfect for a wide range of uses, including machinery labeling, equipment tags, control panels, and safety signs. Below are some common industrial uses for screen-printed aluminum nameplates:

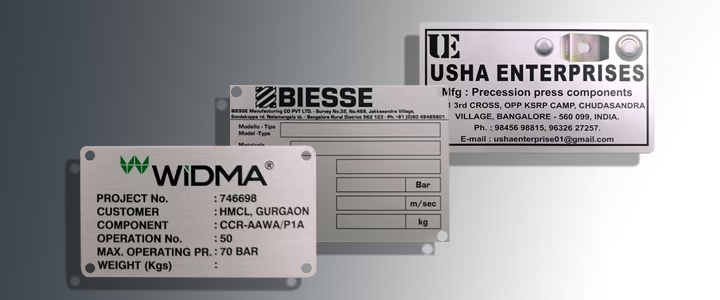

1. Equipment Identification Tags

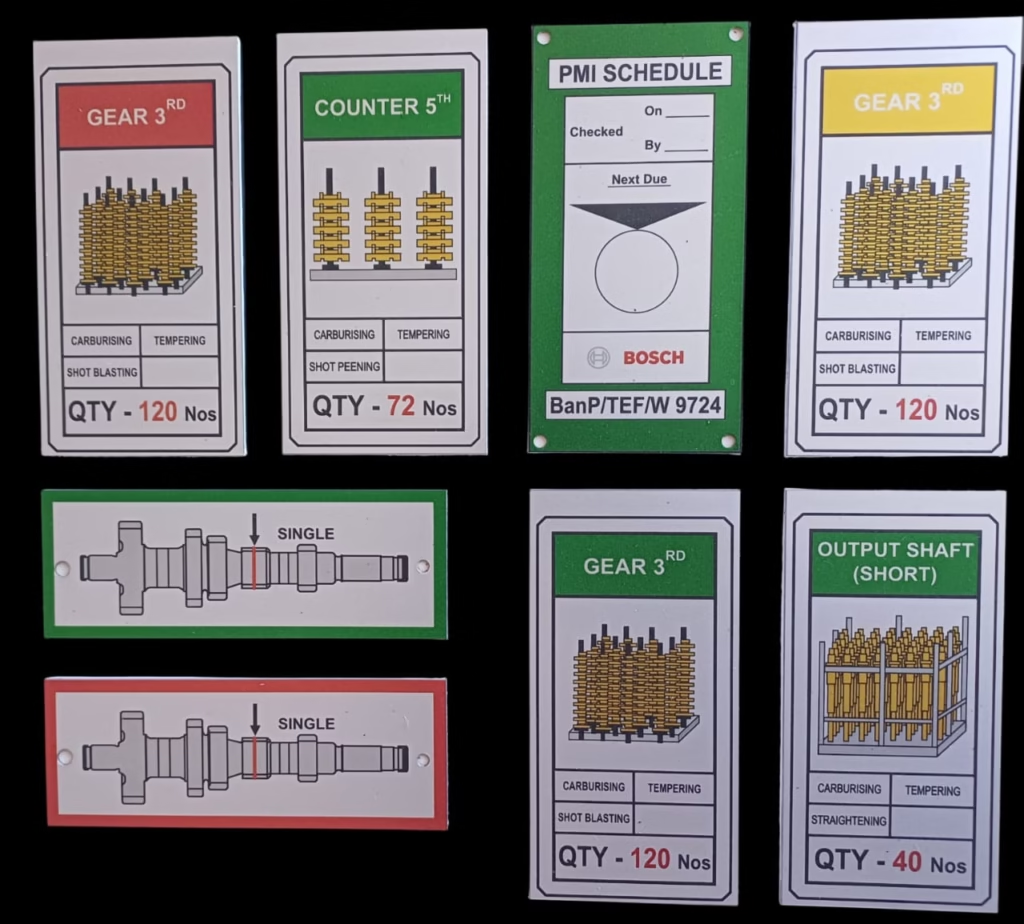

- Purpose: Used to identify machines, tools, or equipment in factories, workshops, and other industrial settings.

- Benefits: They provide clear, long-lasting identification, even in environments where machinery is exposed to chemicals, oils, or extreme temperatures.

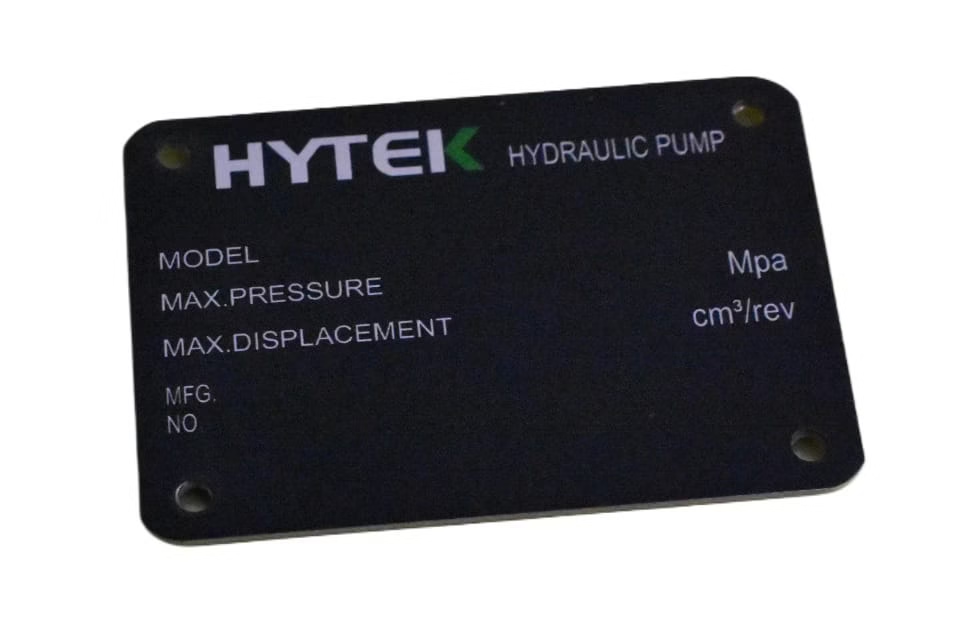

2. Serial Number Plates

- Purpose: To display unique serial numbers or barcodes for tracking and maintenance purposes.

- Benefits: Screen-printed aluminum nameplates are durable and can include important information, such as manufacturing dates, model numbers, and other identifiers.

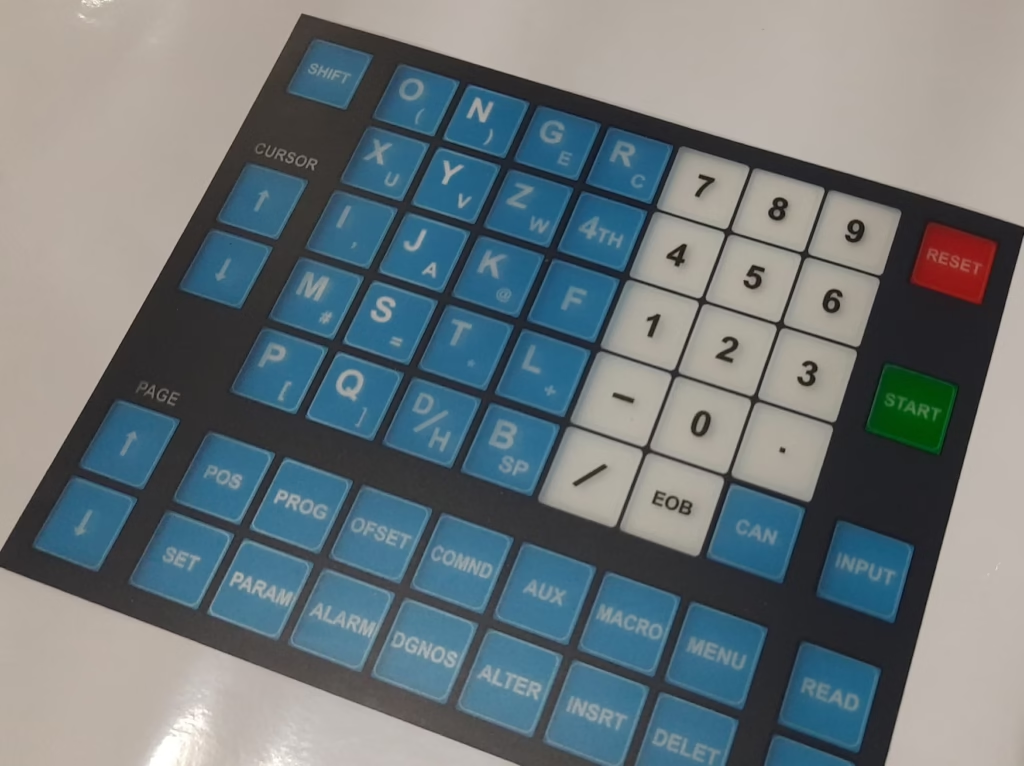

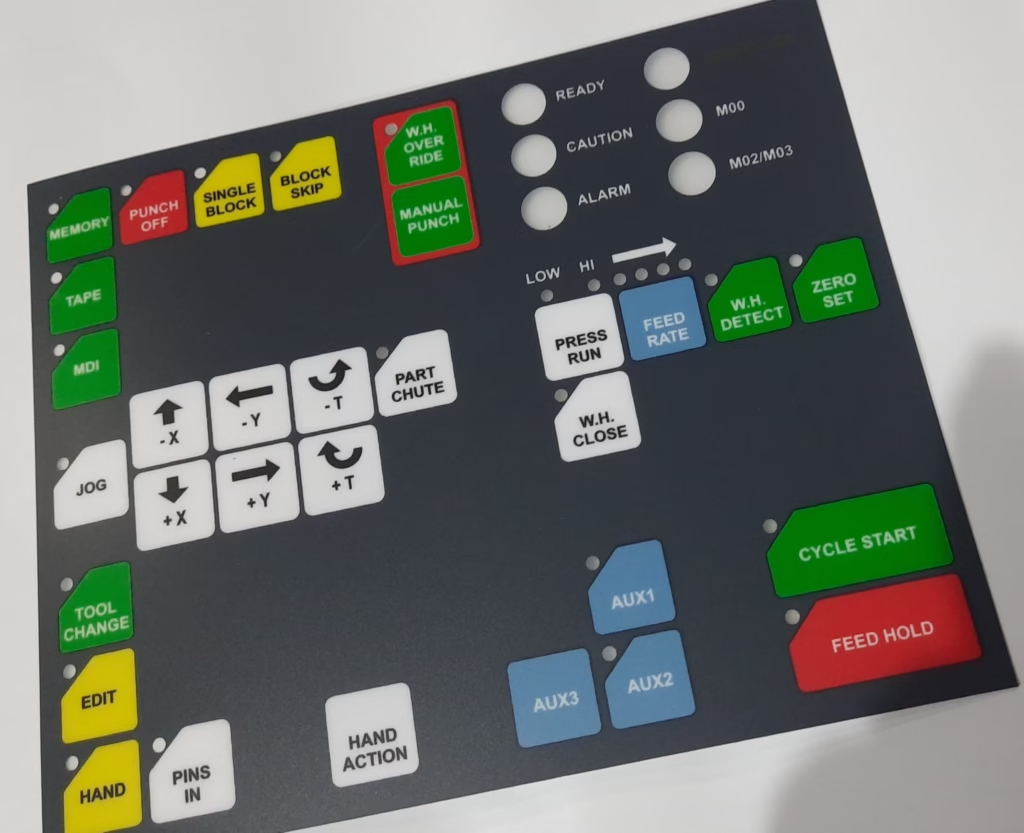

3. Control Panel Labels

- Purpose: Labels that indicate switches, buttons, and other controls on industrial machinery and equipment.

- Benefits: The ink used in screen printing can be highly resistant to fading, ensuring the control labels remain legible for the lifetime of the equipment.

4. Warning and Safety Signage

- Purpose: To provide safety warnings, operational instructions, and hazard signs.

- Benefits: Aluminum nameplates with screen-printed safety information are highly resistant to abrasion and fading, which is critical in maintaining clear safety guidelines in hazardous environments.

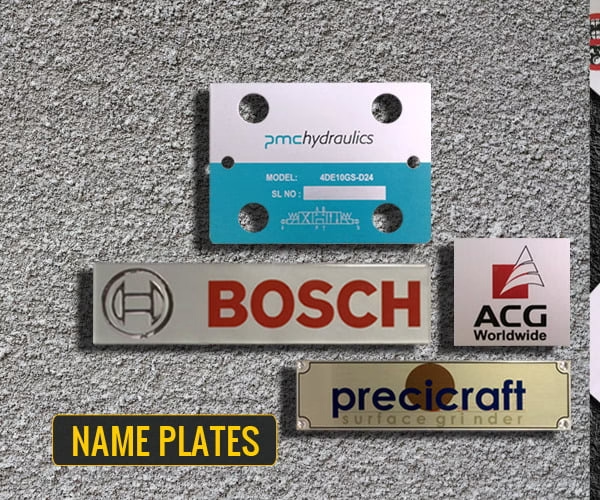

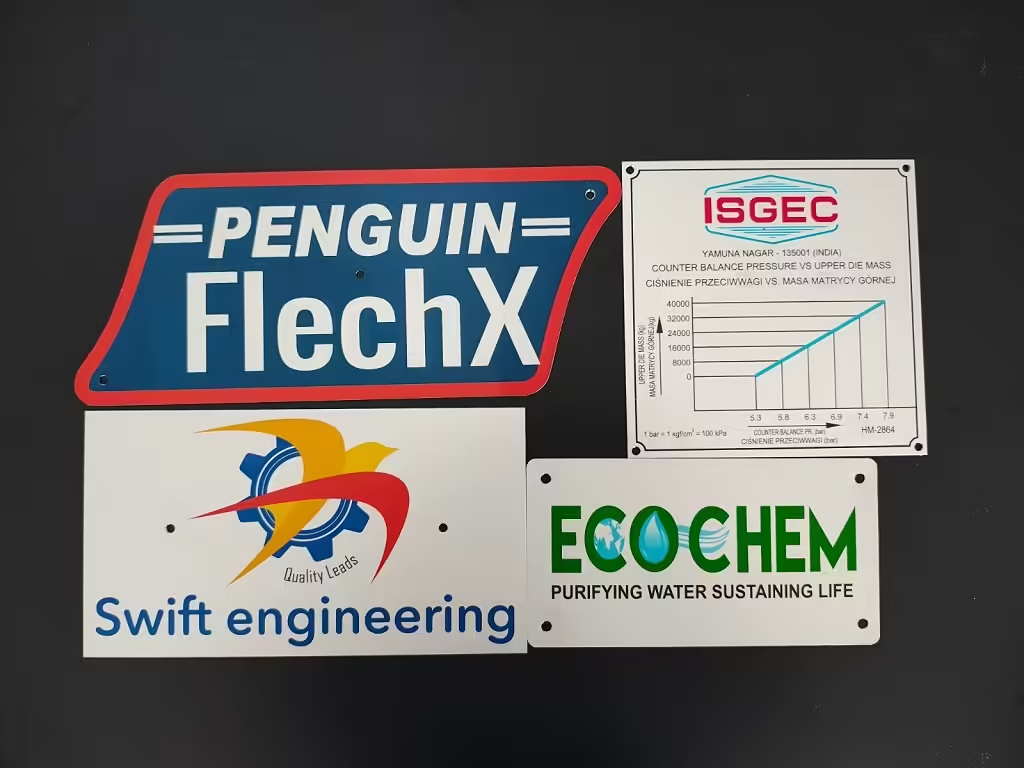

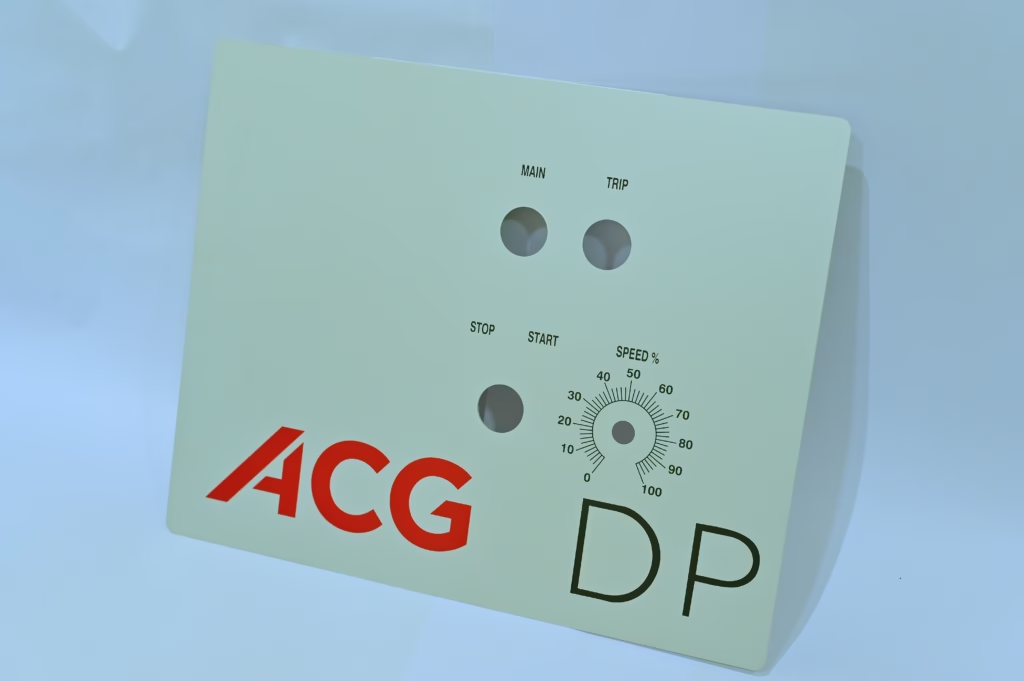

5. Product Branding and Logos

- Purpose: For branding purposes, industrial products often feature screen-printed nameplates displaying company logos and product names.

- Benefits: The process can create intricate designs that withstand the test of time, promoting the brand and providing identification.

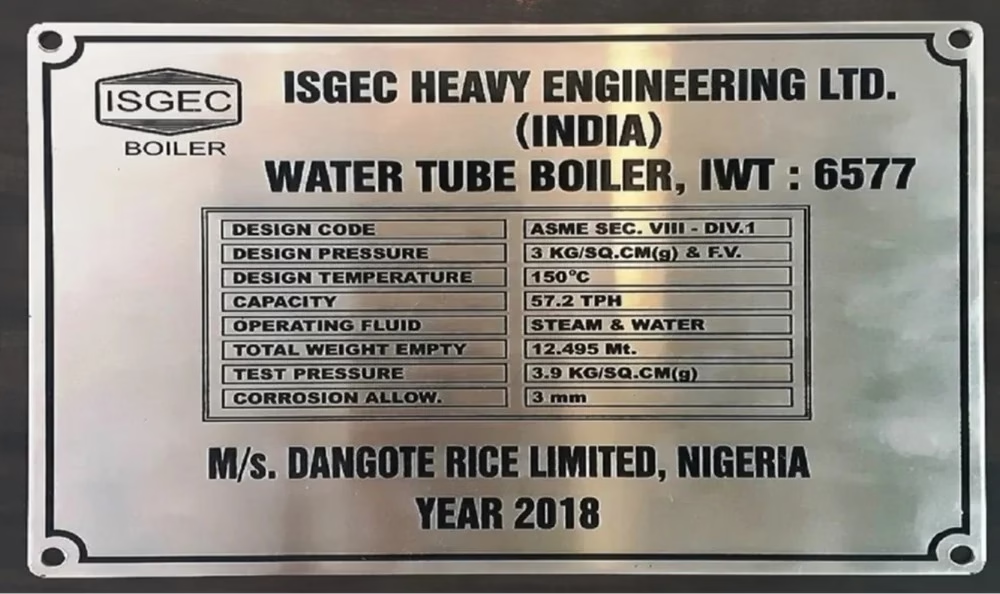

6. Manufacturer’s Plates

- Purpose: Used by manufacturers to display company details, product specifications, and certification information.

- Benefits: The durability of the nameplate ensures the information is visible for a long time, even in challenging industrial environments.

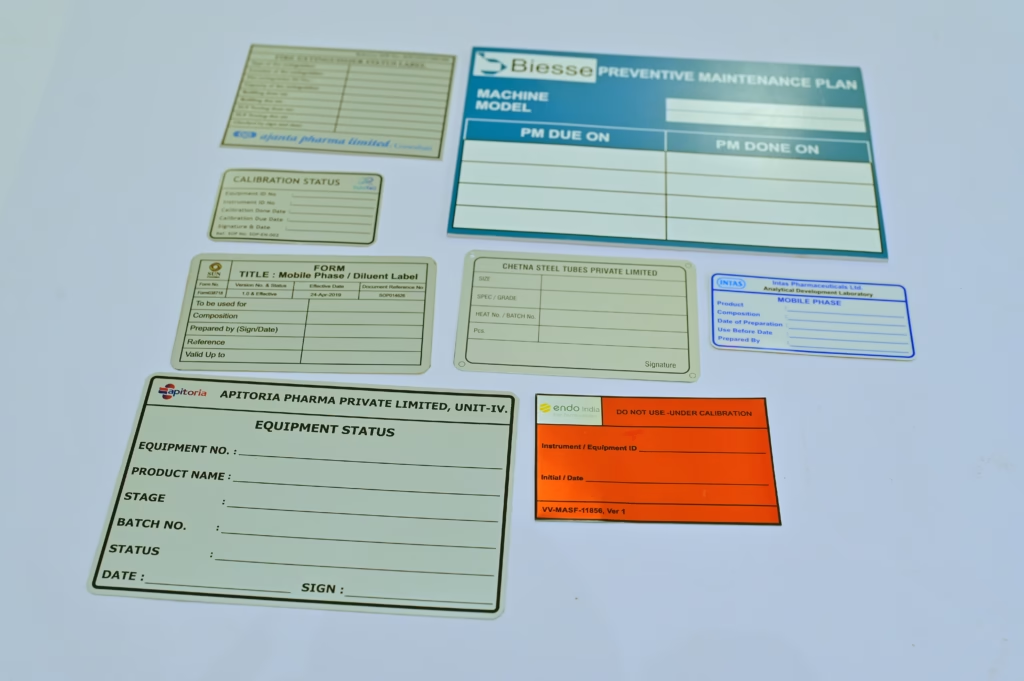

7. Asset Tags for Inventory Management

- Purpose: To track assets and inventory within an industrial setting.

- Benefits: Screen printing allows for the inclusion of QR codes or barcodes, which can be scanned for inventory tracking and management.

8. Outdoor Signage for Equipment

- Purpose: When industrial equipment or machinery is used outdoors, a screen-printed aluminum nameplate ensures long-lasting labeling.

- Benefits: The nameplates are highly resistant to UV rays, water, and other weather elements, making them suitable for outdoor industrial use.

Features & Advantages of Screen-Printed Aluminum Nameplates for Industrial Use:

- Durability: The nameplates are highly resistant to corrosion, scratches, and fading, making them ideal for harsh environments such as factories, plants, and outdoor areas.

- Weather Resistance: They can withstand extreme temperatures, moisture, and UV exposure, which is essential for outdoor or industrial equipment.

- Customization: Screen printing can handle complex designs, logos, and multi-color prints, making it ideal for customized nameplates.

- Legibility: The screen printing process produces high-quality, sharp prints that remain readable for years.

- Cost-Effective: For bulk orders, screen printing can be cost-effective, especially for designs with a limited number of colors.

Materials & Finishes for Industrial Screen-Printed Aluminum Nameplates:

- Anodized Aluminum: Often used for high-quality, corrosion-resistant nameplates.

- Brushed Aluminum: Offers a sleek, industrial aesthetic.

- Colored Aluminum: Can be chosen based on company branding or specific operational needs.

- Clear Coating: Often used as an additional layer to further protect the printed design from wear.

Common Industries that Use Screen-Printed Aluminum Nameplates:

- Manufacturing: For machinery, product identification, and safety labels.

- Automotive: On automotive parts, machinery, and vehicle branding.

- Oil & Gas: Labels for equipment exposed to extreme temperatures and chemicals.

- Construction: For heavy equipment, safety signage, and branding.

- Electronics: For labeling components, control panels, and other machinery.

- Aerospace: Used for high-precision components and equipment.

Conclusion:

Screen-printed aluminum nameplates are an essential component in industrial settings due to their durability, resistance to harsh conditions, and the ability to provide long-lasting, clear information. Whether for safety, identification, branding, or inventory purposes, these nameplates offer a practical and cost-effective solution for various industrial applications.

Would you like more details on any specific type of industrial application or the production process?

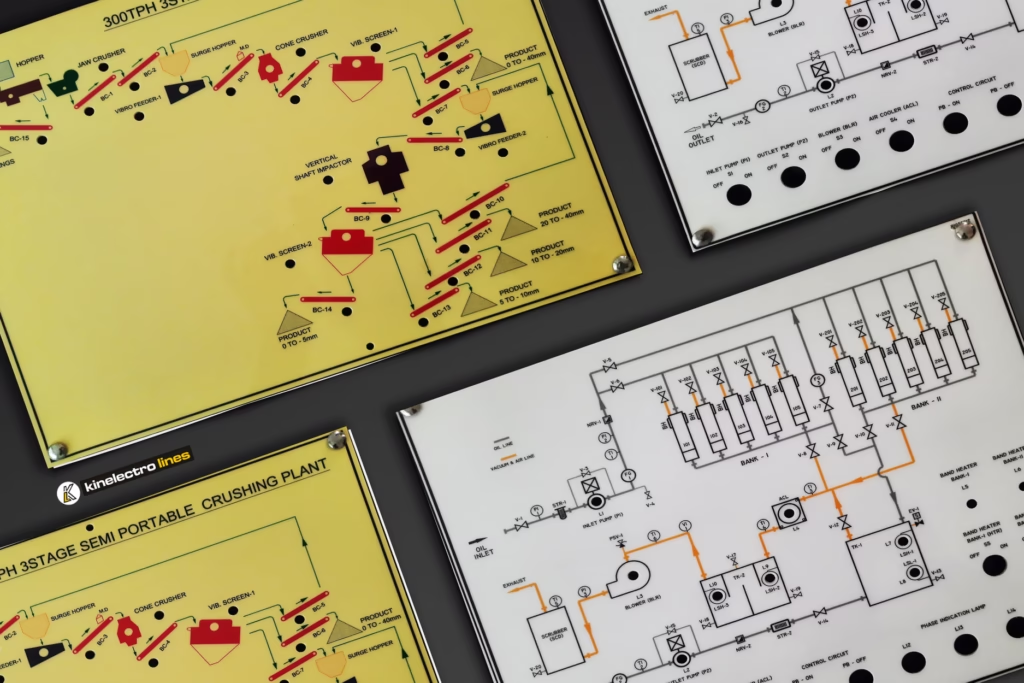

We are also custom manufacture for Industrial applications Anodized Aluminum and Polymer based Name Plates, Fascia Panels, Mimic Panels , Overlays, Decals, Safety Signage, Calibration Labels, Asset Management Labels, and lots more.

Facebook Linkedin Youtube Instagram Pinterest Medium X-twitter