Self-Adhesive Polyester Stickers and Labels

Self-Adhesive Polyester Stickers and Labels The humble sticker and label often go unnoticed in a world saturated with products and information. Yet, these seemingly simple tools play a pivotal role in countless industries, serving as the silent communicators of vital information, powerful branding elements, and indispensable components of logistical efficiency.

Among the vast array of materials used for these applications, self-adhesive polyester stands out as a true workhorse, offering a compelling combination of durability, versatility, and performance. This comprehensive exploration delves deep into self-adhesive polyester stickers and labels, uncovering their unique characteristics, diverse applications, and the reasons behind their widespread adoption.

At their core, self-adhesive polyester stickers and labels comprise two fundamental layers: a printable polyester film and a pressure-sensitive adhesive backing protected by a release liner. This seemingly straightforward construction belies the sophisticated engineering and material science that contribute to their exceptional properties.

Unpacking the Material: Self-Adhesive Polyester Stickers and Labels The Strength and Resilience of Polyester –

Polyester Stickers and Labels

Polyester, also known as polyethylene terephthalate (PET), is a synthetic thermoplastic polymer belonging to the family of polyesters. Its inherent molecular structure imbues it with a remarkable set of characteristics that make it an ideal material for demanding labeling applications.

- Exceptional Strength and Tear Resistance Polyester Stickers

: Polyester films exhibit impressive tensile strength and resistance to tearing and abrasion. This robustness ensures that labels remain intact and legible even when subjected to rough handling, friction, or challenging environmental conditions. Unlike paper-based labels that can easily rip or scuff, polyester labels maintain their integrity, preserving the information they carry.

- Dimensional Stability Polyester Stickers and Labels: Polyester boasts excellent dimensional stability, meaning it resists stretching, shrinking, and warping under varying temperatures and humidity levels. This is crucial for applications where precise alignment and consistent appearance are paramount, such as barcode labeling or intricate product branding.

- Resistance to Environmental Factors Polyester Stickers and Labels: One of the key advantages of polyester is its inherent resistance to a wide range of environmental stressors.

- Moisture and Water Resistance: Polyester is inherently hydrophobic, meaning it repels water and moisture. This makes polyester labels ideal for applications where exposure to dampness, condensation, or even direct contact with liquids is likely, such as food and beverage packaging, outdoor equipment, and laboratory environments.

- Chemical and Solvent Resistance Polyester Stickers and Labels: Polyester exhibits good resistance to many common chemicals, oils, and solvents. This property is vital in industrial and manufacturing settings where labels may come into contact with cleaning agents, lubricants, or other chemical substances. The label’s legibility and adhesion remain unaffected, ensuring critical information is not compromised.

- Temperature Resistance: Polyester films can withstand a broad range of temperatures, from frigid cold to significant heat. Specialized high-temperature polyester labels are engineered to endure even more extreme conditions, making them suitable for applications in automotive engines, industrial ovens, and sterilization processes.

- UV Resistance: Prolonged exposure to ultraviolet (UV) radiation can cause many materials to degrade, leading to fading, yellowing, and embrittlement. Polyester offers good resistance to UV light, ensuring that printed information and label integrity are maintained even in outdoor applications or environments with significant light exposure.

The Power of the Bond: Understanding Self-Adhesive Technology

The self-adhesive backing is the second critical component of these labels, enabling easy and secure application to a diverse range of surfaces without the need for separate adhesives. The pressure-sensitive adhesive (PSA) is typically composed of three main elements:

- Adhesive Polymer: This provides the tackiness and bonding strength. Various types of adhesive polymers are used, including acrylics, rubbers, and silicones, each offering different performance characteristics in terms of adhesion strength, temperature resistance, and removability.

- Tackifier: These additives enhance the initial grab or tack of the adhesive, allowing it to bond quickly and easily upon contact with a surface.

- Other Additives: Depending on the specific application requirements, other additives may be included to modify properties such as flow, cohesion, and resistance to specific chemicals or environmental factors.

The adhesive is coated onto the back of the polyester film and protected by a release liner, typically made of silicone-coated paper or film. This liner prevents the adhesive from sticking prematurely and is easily peeled off when the label is ready for application.

A Spectrum of Choice: Exploring Different Types of Polyester Labels

The versatility of self-adhesive polyester is further enhanced by the availability of various types tailored to specific needs:

- White Polyester Labels: These offer a bright, opaque background that provides excellent contrast for printed text, graphics, and barcodes. They are a versatile choice for general product labeling, branding, and information dissemination.

- Clear Polyester Labels: Providing a “no-label look,” clear polyester labels are ideal for showcasing the product itself while still conveying essential information or branding. They are commonly used in the food and beverage, cosmetics, and personal care industries.

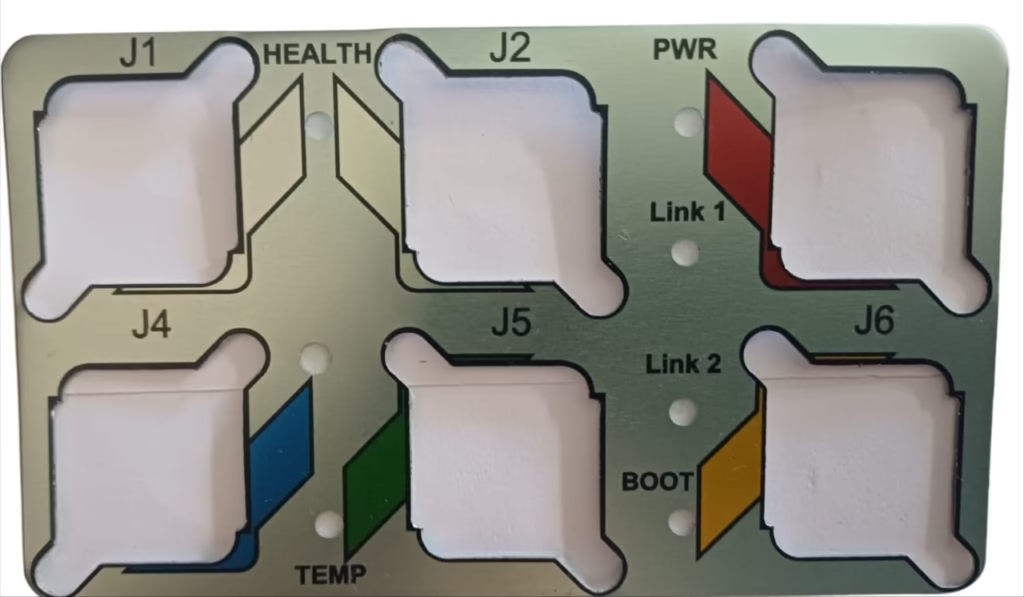

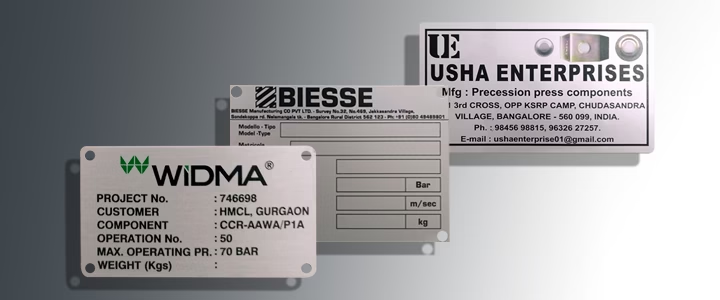

- Silver Polyester Labels: Offering a metallic, premium aesthetic, silver polyester labels add a touch of sophistication to product branding, particularly in electronics, cosmetics, and luxury goods. They can be brushed or glossy, depending on the desired effect.

- Matte Polyester Labels: The non-glossy finish of matte polyester labels reduces glare and reflections, improving readability, especially for applications involving barcodes, serial numbers, or detailed text. They are often preferred in industrial and logistical settings.

- High-Temperature Polyester Labels: Engineered with specialized polyester films and high-performance adhesives, these labels can withstand extreme temperatures without degrading or losing adhesion. They are crucial for labeling components in automotive engines, aerospace equipment, and industrial processes involving heat.

- Low-Tack or Removable Polyester Labels: Designed with adhesives that allow for clean removal without leaving residue, these labels are ideal for temporary applications such as promotional stickers, shelf marking, or asset tracking where labels may need to be repositioned or removed.

- Tamper-Evident Polyester Labels: These specialized labels often feature security slits or a frangible construction. If an attempt is made to remove them, they will either tear apart or leave behind a visible “VOID” message, indicating tampering and ensuring product integrity.

The Canvas for Communication: Printability and Information Conveyance

Polyester films are compatible with a variety of printing technologies, allowing for the creation of high-quality, durable labels that effectively communicate information and brand identity.

- Thermal Transfer Printing: This method uses heat to transfer ink from a ribbon onto the label surface. When paired with resin ribbons, thermal transfer printing on polyester produces exceptionally durable and chemical-resistant prints, ideal for barcode labeling, asset tracking, and industrial applications.

- Laser Printing: Polyester labels specifically designed for laser printers offer a durable and smudge-resistant solution for office and general-purpose labeling.

- Inkjet Printing: While some polyester films are compatible with inkjet printing, the durability and resistance of the printed image may vary depending on the ink type and the specific label material.

The printability of polyester allows for the inclusion of a wide range of information, including:

- Product Identification: Names, descriptions, ingredients, and usage instructions.

- Branding: Logos, company names, and marketing messages.

- Variable Data: Serial numbers, batch codes, date codes, and barcodes for tracking and traceability.

- Safety Information: Warnings, precautions, and hazard symbols.

- Compliance Information: Regulatory markings and certifications.

A World of Applications: Where Polyester Labels Shine

The unique combination of durability, versatility, and printability makes self-adhesive polyester stickers and labels indispensable across a vast spectrum of industries:

- Industrial and Manufacturing: Asset tracking, equipment identification, safety labeling, chemical drum labeling, component marking, and high-temperature applications.

- Electronics: Product labeling, serial number tags, component identification, and warning labels.

- Automotive: Under-the-hood labeling, VIN tags, component identification, and safety warnings.

- Healthcare and Pharmaceuticals: Product labeling, sample identification, laboratory labeling, and sterilization indicators.

- Food and Beverage: Product labeling (resistant to moisture and temperature variations), ingredient lists, nutritional information, and tamper-evident seals.

- Retail and Logistics: Barcode labeling, shelf marking, price tags, promotional stickers, and shipping labels.

- Outdoor and Environmental: Equipment marking, signage, warning labels, and asset tracking in challenging weather conditions.

- Aerospace: Component identification, safety markings, and high-temperature applications.

The Advantages are Clear: Why Choose Polyester?

The widespread adoption of self-adhesive polyester stickers and labels is a testament to their numerous advantages over alternative materials:

- Superior Durability: Outperforms paper and vinyl in terms of tear resistance, abrasion resistance, and longevity in demanding environments.

- Excellent Resistance to Environmental Factors: Holds up better against moisture, chemicals, temperature extremes, and UV exposure compared to less robust materials.

- Versatility Across Applications: Suitable for a wide range of indoor and outdoor uses across diverse industries.

- High-Quality Printability: Compatible with various printing methods, ensuring clear, sharp, and durable printed information.

- Professional Appearance: Available in various finishes (gloss, matte, clear, silver) to enhance product aesthetics and brand image.

- Long Lifespan: Ensures that critical information remains legible and the label remains adhered for the intended duration.

- Cost-Effectiveness: While the initial material cost may be slightly higher than some alternatives, the superior durability and longevity often result in lower replacement costs and reduced errors due to label failure.

Looking Ahead: The Future of Polyester Labeling

As technology continues to advance, so too will the capabilities of self-adhesive polyester stickers and labels. Ongoing innovations are focusing on:

- Enhanced Adhesives: Developing even stronger, more temperature-resistant, and residue-free adhesives for specialized applications.

- Sustainable Materials: Exploring bio-based polyester films and more environmentally friendly adhesive options.

- Smart Labels: Integrating technologies like RFID (Radio-Frequency Identification) and NFC (Near-Field Communication) into polyester labels for enhanced tracking, authentication, and data collection.

- Improved Print Technologies: Developing printing methods that offer even greater durability, color vibrancy, and customization options on polyester films.

Conclusion: The Indispensable Role of

Polyester Stickers and Labels

Self-adhesive polyester stickers and labels are far more than just simple identifiers. They are robust, reliable, and versatile tools that play a critical role in product branding, information dissemination, safety communication, and logistical efficiency across a multitude of industries.

Their inherent strength, resistance to environmental factors, and compatibility with various printing technologies make them the preferred choice for applications demanding durability and longevity.

As technology continues to evolve, the unsung heroes of identification and branding – self-adhesive polyester stickers and labels – will undoubtedly continue to adapt and innovate, solidifying their indispensable role in our increasingly complex and information-driven world.

Their ability to withstand the rigors of diverse environments while effectively conveying crucial information ensures their continued relevance and importance for years to come.

Polyester Stickers and Labels