Aluminum and stainless steel nameplates differ in several aspects, including material properties, appearance, durability, and applications.

Here’s a breakdown of the key differences:

1. Name plates Material Composition

- Aluminum Nameplates: Made from lightweight aluminum, typically alloyed for added strength and corrosion resistance.

- Stainless Steel Nameplates: Made from various grades of stainless steel, which contains iron, chromium, and sometimes nickel, offering exceptional corrosion resistance.

2. Name plates Weight

- Aluminum: Lightweight, making it suitable for applications where weight is a concern.

- Stainless Steel: Heavier and more robust, ideal for heavy-duty or industrial uses.

3. Name plates Durability

- Aluminum: Resistant to corrosion and weathering but can be prone to scratches and dents due to its softer nature.

- Stainless Steel: Extremely durable, resistant to corrosion, scratches, and high temperatures, making it suitable for harsh environments.

4. Name plates Appearance

- Aluminum: Has a silvery, matte finish that can be anodized or coated for different colors and textures.

- Stainless Steel: Features a polished or brushed metallic finish, offering a sleek, modern, and professional look.

5.Name plates Corrosion Resistance

- Aluminum: Naturally resistant to corrosion due to its protective oxide layer, but not as resistant to strong chemicals or saline environments as stainless steel.

- Stainless Steel: Superior corrosion resistance, especially in high-moisture, chemical, or saltwater environments.

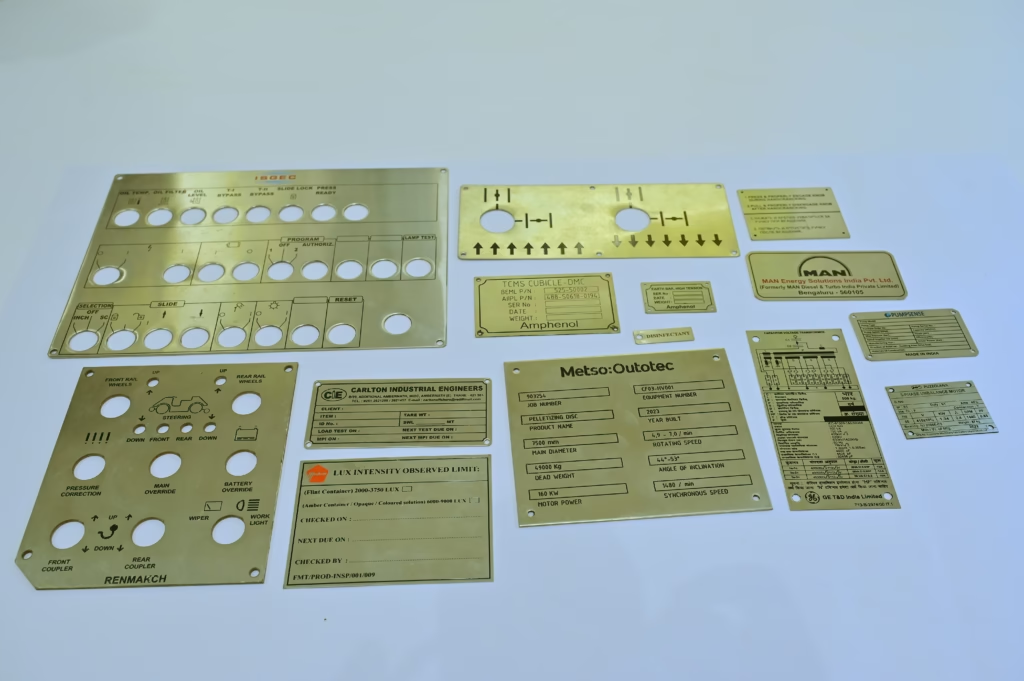

6.Nameplates Customization

- Aluminum: Easier to fabricate, engrave, and anodize for colored finishes or intricate designs.

- Stainless Steel: Can also be engraved, laser-etched, or embossed but is harder to work with due to its toughness.

7. Cost

- Aluminum: Generally more affordable, especially for large-scale production.

- Stainless Steel: More expensive due to its material cost and processing requirements.

8. Applications

- Aluminum: Commonly used for indoor signage, lightweight machinery, office settings, and decorative purposes.

- Stainless Steel: Preferred for industrial, marine, or outdoor applications where durability and corrosion resistance are critical.

Summary

- Choose Aluminum if you need lightweight, affordable, and customizable nameplates for less demanding environments.

- Choose Stainless Steel if you require high durability, superior corrosion resistance, and a premium look for harsh or industrial environments.

Scratch Test

- Aluminum: Softer and more prone to scratches. You can lightly scratch it with a key or nail.

- Stainless Steel: Much harder and more resistant to scratches.

Oxidation and Corrosion

- Aluminum: Forms a white, chalky layer of aluminum oxide when exposed to air for extended periods. Not prone to rust.

- Stainless Steel: Doesn’t rust under normal conditions. If exposed to harsh environments, it may develop minor discoloration but no white oxide layer.

Sound Test

- Aluminum: Produces a duller sound when tapped.

- Stainless Steel: Produces a sharper, more ringing sound.

Heat Test

- Aluminum: Heats up quickly and dissipates heat rapidly.

- Stainless Steel: Slower to heat up and retains heat longer.

Chemical Test (Optional)

- Use a small amount of sodium hydroxide (NaOH) (commonly found in drain cleaners):

- Aluminum: Reacts with NaOH to produce bubbles and a white residue.

- Stainless Steel: No significant reaction.

Cost Perception

- If the nameplate feels lightweight and has a more basic finish, it is likely aluminum.

- If it feels premium, heavy, and has a professional, polished look, it is likely stainless steel.

Using a combination of these tests will help you accurately identify the material of the nameplate.